Page 57 - TURNING CATALOG p255-458

P. 57

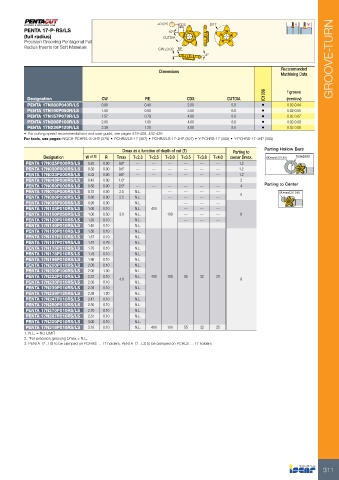

±0.025 CDX Ø17 IC1008

4°

PENTA 17-P-RS/LS 10° GROOVE-TURN

(full radius) CUTDIA

Precision Grooving Pentagonal Full

Radius Inserts for Soft Materials CW ±0.02 RE

Dimensions Recommended

Machining Data

Designation CW RE CDX CUTDIA f groove

5.0 •

PENTA 17N080P040R/LS 0.80 0.40 2.50 6.0 • (mm/rev)

0.02-0.04

PENTA 17N100P050R/LS 1.00 0.50 3.00 8.0 • 0.02-0.05

0.02-0.07

PENTA 17N157P079R/LS 1.57 0.79 4.00 8.0 • 0.02-0.08

0.02-0.08

PENTA 17N200P100R/LS 2.00 1.00 4.00 8.0 •

PENTA 17N239P120R/LS 2.39 1.20 4.00

• For cutting speed recommendations and user guide, see pages 419-428, 432-436

For tools, see pages: NQCH-PCHR/L-S-JHP (378) • PCHRS/LS-17 (307) • PCHRS/LS-17-JHP (307) • Y-PCHRS-17 (308) • Y-PCHRS-17-JHP (308)

Dmax as a function of depth of cut (T) Parting to Parting Hollow Bars

center Dmax.

Designation W ±0.02 R Tmax T<2.3 T<2.5 T<3.0 T<3.5 T<3.8 T<4.0 ØDmax(CUTDIA) Tmax(CDX)

1.2

PENTA 17N025P000RS/LS 0.25 0.00 0.6* --- --- --- --- --- --- 1.2

1.2

PENTA 17N030P000RS/LS 0.30 0.00 0.6* --- --- --- --- --- --- 2

4

PENTA 17N033P000RS/LS 0.33 0.00 0.6* --- --- --- --- --- --- 5

PENTA 17N043P000RS/LS 0.43 0.00 1.0* --- --- --- --- --- --- 6 Parting to Center

PENTA 17N050P000RS/LS 0.50 0.00 2.0* --- --- --- --- --- --- 8 ØDmax(CUTDIA)

PENTA 17N075P000RS/LS 0.75 0.00 2.5 N.L. --- --- --- ---

PENTA 17N080P000RS/LS 0.80 0.00 2.5 N.L. --- --- --- ---

PENTA 17N095P000RS/LS 0.95 0.00 N.L. --- --- ---

PENTA 17N100P010RS/LS 1.00 0.10 N.L. 400 --- --- ---

PENTA 17N100P050RS/LS 1.00 0.50 3.0 N.L. 100 --- --- ---

PENTA 17N120P010RS/LS 1.20 0.10 N.L. --- --- ---

PENTA 17N140P010RS/LS 1.40 0.10 N.L. --- --- ---

PENTA 17N150P010RS/LS 1.50 0.10 N.L.

PENTA 17N157P010RS/LS 1.57 0.10 N.L.

PENTA 17N157P079RS/LS 1.57 0.79 N.L.

PENTA 17N170P010RS/LS 1.70 0.10 N.L.

PENTA 17N178P010RS/LS 1.78 0.10 N.L.

PENTA 17N196P010RS/LS 1.96 0.10 N.L.

PENTA 17N200P010RS/LS 2.00 0.10 N.L.

PENTA 17N200P100RS/LS 2.00 1.00 N.L.

PENTA 17N222P010RS/LS 2.22 0.10 4.0 N.L. 400 100 55 32 20

PENTA 17N230P010RS/LS 2.30 0.10 N.L.

PENTA 17N239P010RS/LS 2.39 0.10 N.L.

PENTA 17N239P120RS/LS 2.39 1.20 N.L.

PENTA 17N247P010RS/LS 2.47 0.10 N.L.

PENTA 17N250P010RS/LS 2.50 0.10 N.L.

PENTA 17N270P010RS/LS 2.70 0.10 N.L.

PENTA 17N287P010RS/LS 2.87 0.10 N.L.

PENTA 17N300P010RS/LS 3.00 0.10 N.L.

PENTA 17N318P010RS/LS 3.18 0.10 N.L. 400 100 55 32 25

1. N.L. = NO LIMIT

2. *For precision grooving Dmax = N.L.

3. PENTA 17...RS to be clamped on PCHRS ...-17 holders, PENTA 17...LS to be clamped on PCHLS ...-17 holders.

311