Page 88 - TURNING CATALOG p635-848

P. 88

THREADING USER GUIDE

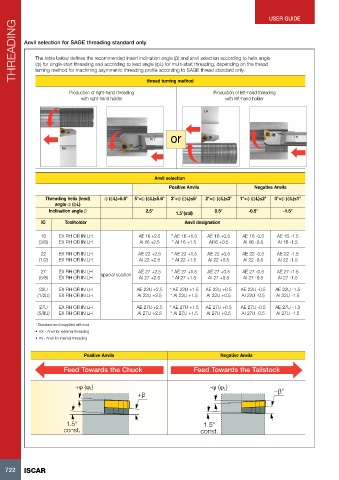

Anvil selection for SAGE threading standard only

The table below defines the recommended insert inclination angle (β) and anvil selection according to helix angle

(φ) for single-start threading and according to lead angle (φL) for multi-start threading, depending on the thread

turning method for machining asymmetric threading profile according to SAGE thread standard only.

thread turning method

Production of right-hand threading Production of left-hand threading

with right-hand holder with left-hand holder

LH

orRH LH

RH

Threading helix (lead) Anvil selection Negative Anvils

angle φ (φL) Positive Anvils 1°<φ (φL)≤2° 0°<φ (φL)≤1°

Inclination angle β φ (φL)>5.6° 5°<φ (φL)≤5.6° 3°<φ (φL)≤5° 2°<φ (φL)≤3°

lC Toolholder 2.5° 1.5°(std) 0.5° -0.5° -1.5°

Anvil designation

16 EX RH OR IN LH AE 16 +2.5 * AE 16 +1.5 AE 16 +0.5 AE 16 -0.5 AE 16 -1.5

(3/8) EX RH OR IN LH AI 16 +2.5 * AI 16 +1.5 AI16 +0.5 AI 16 -0.5 AI 16 -1.5

22 EX RH OR IN LH AE 22 +2.5 * AE 22 +1.5 AE 22 +0.5 AE 22 -0.5 AE 22 -1.5

(1/2) EX RH OR IN LH AI 22 +2.5 * AI 22 +1.5 AI 22 +0.5 AI 22 -0.5 AI 22 -1.5

27 EX RH OR IN LH special solution AE 27 +2.5 * AE 27 +1.5 AE 27 +0.5 AE 27 -0.5 AE 27 -1.5

(5/8) EX RH OR IN LH AI 27 +2.5 * AI 27 +1.5 AI 27 +0.5 AI 27 -0.5 AI 27 -1.5

22U EX RH OR IN LH AE 22U +2.5 * AE 22U +1.5 AE 22U +0.5 AE 22U -0.5 AE 22U -1.5

(1/2U) EX RH OR IN LH AI 22U +2.5 * AI 22U +1.5 AI 22U +0.5 AI 22U -0.5 AI 22U -1.5

27U EX RH OR IN LH AE 27U +2.5 * AE 27U +1.5 AE 27U +0.5 AE 27U -0.5 AE 27U -1.5

(5/8U) EX RH OR IN LH AI 27U +2.5 * AI 27U +1.5 AI 27U +0.5 AI 27U -0.5 AI 27U -1.5

* Standard anvil supplied with tool

• EX - Anvil for external threading

• IN - Anvil for internal threading

Positive Anvils Negative Anvils

Feed Towards the Chuck Feed Towards the Tailstock

+φ (φL) +β -φ (φL) −β°

1.5° 1.5°

const. const.

722 ISCAR