Page 90 - TURNING CATALOG p635-848

P. 90

THREADING USER GUIDE

Depth per Pass and Number of Passes

In order to produce threads, the cutting tool needs to make several numbers of cuts along the workpiece surface. The

parameters of depth per pass and number of passes have a very important role in threading production. These parameters have

a direct effect on cutting edge wear, tool life, threading surface quality, and threading production stability.

The two methods most common in determining the depth per pass and the number of passes are constant chip area by

decreasing depth per pass or constant depth per pass. The choice of method does not depend on the selected infeed methods

(radial infeed, flank infeed, modified flank infeed, alternating flank infeed), which are described in chapter 2.12.

The depth per pass and number of passes parameters depend on the type of equipment, tool overhang, machine stability,

workpiece material, cutter geometry and the threading depth required.

Constant chip area by decreasing depth per pass (recommended)

This is the most common method and is generally recommended, as in most cases it ensures high productivity. The principle of

this method is that the initial cutting depth at the first pass is the largest, and then gradually decreases at each pass to ensure

material removal within a constant chip area.

The calculation of passes is designed so that the last pass, which is destined to be a finish pass, will be 0.05 - 0.1 mm (0.0019

- 0.0039 inches). Using this method ensures constant loads on cutting edge and uniform wear, which increases tool life.

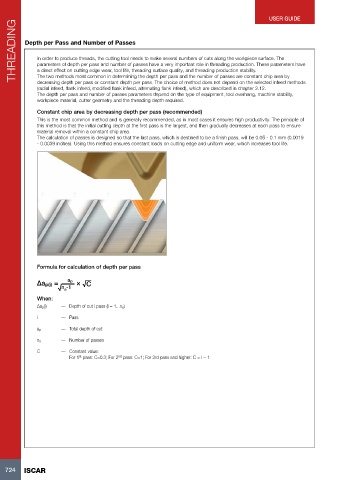

Formula for calculation of depth per pass

∆ap(i) =√na-a1p × √C

When: — Depth of cut i pass (i = 1...na)

∆ap(i)

i — Pass

ap — Total depth of cut

na — Number of passes

C — Constant value:

For 1st pass: C=0.3; For 2nd pass: C=1; For 3rd pass and higher: C = i − 1

724 ISCAR