Page 53 - Iscars_World_Brochure_2018

P. 53

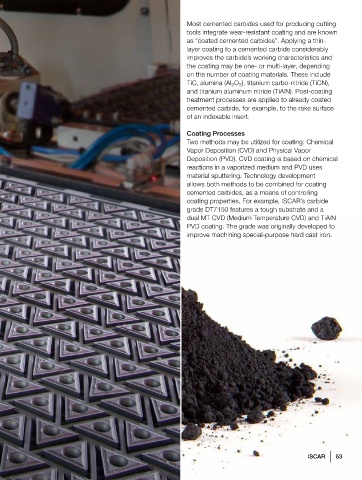

Most cemented carbides used for producing cutting

tools integrate wear-resistant coating and are known

as “coated cemented carbides”. Applying a thin-

layer coating to a cemented carbide considerably

improves the carbide’s working characteristics and

the coating may be one- or multi-layer, depending

on the number of coating materials. These include

3

TiC, alumina (Al 2 O ), titanium carbo-nitride (TiCN),

and titanium aluminum nitride (TiAlN). Post-coating

treatment processes are applied to already coated

cemented carbide, for example, to the rake surface

of an indexable insert.

Coating Processes

Two methods may be utilized for coating: Chemical

Vapor Deposition (CVD) and Physical Vapor

Deposition (PVD). CVD coating is based on chemical

reactions in a vaporized medium and PVD uses

material sputtering. Technology development

allows both methods to be combined for coating

cemented carbides, as a means of controlling

coating properties. For example, ISCAR’s carbide

grade DT7150 features a tough substrate and a

dual MT CVD (Medium Temperature CVD) and TiAlN

PVD coating. The grade was originally developed to

improve machining special-purpose hard cast iron.

ISCAR 53