Page 92 - HOLE_MAKING_CATALOG_INCH_2022_P1-P186

P. 92

USER GUIDE

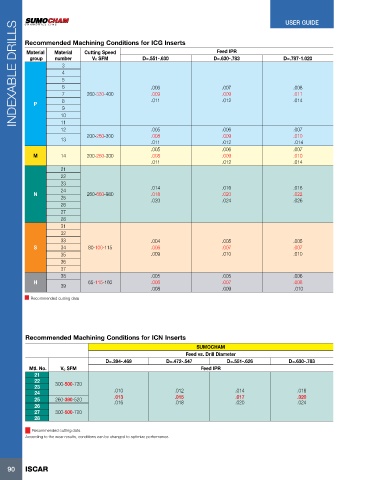

INDEXABLE DRILLS Recommended Machining Conditions for ICG Inserts D=.630-.783 D=.787-1.020

Feed IPR

Material

Cutting Speed

Material

D=.551-.630

number

Vc SFM

group

3

4

5

6

.006

.008

.007

.009

.011

7

.009

260-330-400

.012

.011

.014

8

P

9

10

11

12 .005 .006 .007

200-260-300 .008 .009 .010

13

.011 .012 .014

.005 .006 .007

M 14 200-260-300 .008 .009 .010

.011 .012 .014

21

22

23

24 .014 .016 .018

N 260-660-980 .018 .020 .022

25 .020 .024 .026

26

27

28

31

32

33 .004 .005 .005

S 34 80-100-115 .006 .007 .007

35 .009 .010 .010

36

37

38 .005 .005 .006

H 65-115-160 .006 .007 .008

39 .008 .009 .010

Recommended cutting data

Recommended Machining Conditions for ICN Inserts

SUMOCHAM

Feed vs. Drill Diameter

D=.394-.469 D=.472-.547 D=.551-.626 D=.630-.783

Mtl. No. Vc SFM Feed IPR

21

22 300-500-720

23

24 .010 .012 .014 .016

25 260-390-520 .013 .015 .017 .020

.024

.020

.018

.016

26

27 300-500-720

28

Recommended cutting data

According to the wear results, conditions can be changed to optimize performance.

90 ISCAR