Page 93 - HOLE_MAKING_CATALOG_INCH_2022_P1-P186

P. 93

USER GUIDE

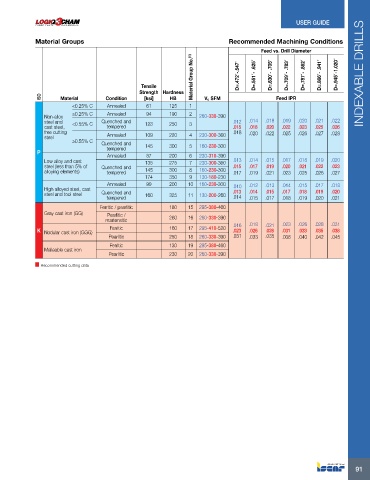

Material Groups Recommended Machining Conditions

Feed vs. Drill Diameter

Material Group No. (1) D=.472”-.547” D=.551”- .625” D=.630”- .705” D=.709”- .783” D=.787”- .862” D=.866”- .941” D=.945”-1.020” INDEXABLE DRILLS

Tensile

Strength Hardness

ISO Material Condition [ksi] HB Vc SFM Feed IPR

<0.25% C Annealed 61 125 1

Non-alloy ≥0.25% C Annealed 94 190 2 260-330-390

steel and <0.55% C Quenched and 123 250 3 .012 .014 .018 .019 .020 .021 .022

cast steel, tempered .015 .018 .020 .022 .023 .025 .026

free cutting Annealed 109 220 4 230-300-360 .018 .020 .022 .025 .026 .027 .028

steel

≥0.55% C Quenched and

tempered 145 300 5 160-230-300

P

Annealed 87 200 6 230-310-390

Low alloy and cast 135 275 7 230-300-360 .013 .014 .015 .017 .018 .019 .020

steel (less than 5% of Quenched and .015 .017 .019 .020 .021 .022 .023

alloying elements) tempered 145 300 8 160-230-300 .017 .019 .021 .023 .025 .026 .027

174 350 9 130-180-230

Annealed 99 200 10 160-230-300 .010 .012 .013 .014 .015 .017 .018

High alloyed steel, cast .013 .014 .015 .017 .018 .019 .020

steel and tool steel Quenched and 160 325 11 130-200-260

tempered .014 .015 .017 .018 .019 .020 .021

Ferritic / pearlitic 180 15 295-380-460

Gray cast iron (GG) Pearlitic /

martensitic 260 16 260-330-390 .016 .018 .021 .023 .026 .028 .031

K Nodular cast iron (GGG) Ferritic 160 17 295-410-520 .023 .026 .028 .031 .033 .035 .038

Pearlitic 250 18 260-330-390 .031 .033 .035 .038 .040 .042 .045

Ferritic 130 19 295-380-460

Malleable cast iron

Pearlitic 230 20 260-330-390

Recommended cutting data

91