Page 33 - HOLE_MAKING_CATALOG_INCH_2022_P187-P236

P. 33

OAL MQL

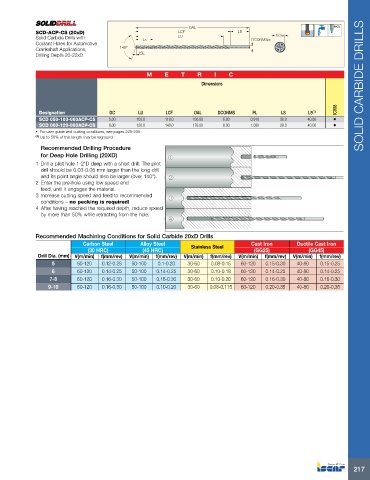

SCD-ACP-CS (20xD) LCF LS

Solid Carbide Drills with L5 LU DCONMSh6 DCh8

Coolant Holes for Automotive

Crankshaft Applications, 140º

Drilling Depth 20-22xD PL

M E T R I C

Dimensions SOLID CARBIDE DRILLS

IC908

Designation DC LU LCF OAL DCONMS PL LS L5 (1)

SCD 050-103-060ACP-CS 5.00 103.0 118.0 156.00 6.00 0.910 38.0 40.00 •

SCD 060-120-060ACP-CS 6.00 120.0 140.0 178.00 6.00 1.090 38.0 40.00 •

• For user guide and cutting conditions, see pages 225-235

(1) Up to 50% of this length may be reground

Recommended Drilling Procedure

for Deep Hole Drilling (20XD) 1

1 Drill a pilot hole 1-2*D deep with a short drill. The pilot

drill should be 0.03-0.05 mm larger than the long drill

and its point angle should also be larger (over 140°). 2

2 Enter the pre-hole using low speed and

feed, until it engages the material.

3 Increase cutting speed and feed to recommended 3

conditions – no pecking is required!

4 After having reached the required depth, reduce speed

by more than 50% while retracting from the hole.

4

Recommended Machining Conditions for Solid Carbide 20xD Drills

Carbon Steel Alloy Steel Stainless Steel Cast Iron Ductile Cast Iron

(30 HRC) (45 HRC) (GG25) (GG45)

Drill Dia. (mm) V(m/min) f(mm/rev) V(m/min) f(mm/rev) V(m/min) f(mm/rev) V(m/min) f(mm/rev) V(m/min) f(mm/rev)

5 60-120 0.12-0.25 50-100 0.1-0.20 30-60 0.08-0.15 60-120 0.15-0.30 40-80 0.15-0.25

6 60-120 0.14-0.25 50-100 0.14-0.25 30-60 0.10-0.18 60-120 0.14-0.25 40-80 0.14-0.25

7-8 60-120 0.16-0.30 50-100 0.16-0.30 30-60 0.10-0.20 60-120 0.16-0.30 40-80 0.16-0.30

9-10 60-120 0.16-0.30 50-100 0.10-0.20 30-60 0.08-0.115 60-120 0.20-0.35 40-80 0.20-0.35

217