Page 38 - HOLE_MAKING_CATALOG_INCH_2022_P187-P236

P. 38

SOLID CARBIDE DRILLS

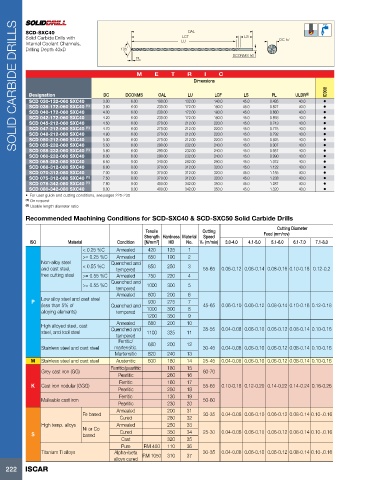

SCD-SXC40 OAL

Solid Carbide Drills with LCF LS DC h7

Internal Coolant Channels, LU

Drilling Depth 40xD 135

DCONMS h6

PL

M E T R I C

Dimensions

IC908

Designation DC DCONMS OAL LU LCF LS PL ULDR (2)

SCD 030-132-060 SXC40 3.00 6.00 190.00 132.00 140.0 45.0 0.495 40.0 •

SCD 038-172-060 SXC40 (1) 3.80 6.00 230.00 172.00 180.0 45.0 0.627 40.0 •

SCD 040-172-060 SXC40 4.00 6.00 230.00 172.00 180.0 45.0 0.660 40.0 •

SCD 042-172-060 SXC40 4.20 6.00 230.00 172.00 180.0 45.0 0.693 40.0 •

SCD 045-212-060 SXC40 4.50 6.00 270.00 212.00 220.0 45.0 0.743 40.0 •

SCD 047-212-060 SXC40 (1) 4.70 6.00 270.00 212.00 220.0 45.0 0.775 40.0 •

SCD 048-212-060 SXC40 4.80 6.00 270.00 212.00 220.0 45.0 0.792 40.0 •

SCD 050-212-060 SXC40 5.00 6.00 270.00 212.00 220.0 45.0 0.825 40.0 •

SCD 055-232-060 SXC40 5.50 6.00 290.00 232.00 240.0 45.0 0.907 40.0 •

SCD 058-232-060 SXC40 (1) 5.80 6.00 290.00 232.00 240.0 45.0 0.957 40.0 •

SCD 060-232-060 SXC40 6.00 6.00 290.00 232.00 240.0 45.0 0.990 40.0 •

SCD 065-282-080 SXC40 6.50 8.00 340.00 282.00 290.0 45.0 1.072 40.0 •

SCD 068-312-080 SXC40 6.80 8.00 370.00 312.00 320.0 45.0 1.122 40.0 •

SCD 070-312-080 SXC40 7.00 8.00 370.00 312.00 320.0 45.0 1.155 40.0 •

SCD 075-312-080 SXC40 (1) 7.50 8.00 370.00 312.00 320.0 45.0 1.238 40.0 •

SCD 078-342-080 SXC40 (1) 7.80 8.00 400.00 342.00 350.0 45.0 1.287 40.0 •

SCD 080-342-080 SXC40 8.00 8.00 400.00 342.00 350.0 45.0 1.320 40.0 •

• For user guide and cutting conditions, see pages 225-235

(1) On request

(2) Usable length diameter ratio

Recommended Machining Conditions for SCD-SXC40 & SCD-SXC50 Solid Carbide Drills

Cutting Diameter

Tensile Cutting Feed (mm/rev)

Strength Hardness Material Speed

2

ISO Material Condition [N/mm ] HB No. Vc (m/min) 3.0-4.0 4.1-5.0 5.1-6.0 6.1-7.0 7.1-8.0

< 0.25 %C Annealed 420 125 1

>= 0.25 %C Annealed 650 190 2

Non-alloy steel Quenched and

and cast steel, < 0.55 %C tempered 850 250 3 55-65 0.06-0.12 0.06-0.14 0.08-0.16 0.10-0.18 0.12-0.2

free cutting steel >= 0.55 %C Annealed 750 220 4

Quenched and

>= 0.55 %C 1000 300 5

tempered

Annealed 600 200 6

P Low alloy steel and cast steel 930 275 7

(less than 5% of Quenched and 1000 300 8 45-65 0.06-0.10 0.06-0.12 0.08-0.14 0.10-0.16 0.12-0.18

alloying elements) tempered

1200 350 9

High alloyed steel, cast Annealed 680 200 10

steel, and tool steel Quenched and 1100 325 11 35-55 0.04-0.08 0.06-0.10 0.06-0.12 0.08-0.14 0.10-0.16

tempered

Ferritic/ 680 200 12

Stainless steel and cast steel martensitic. 30-45 0.04-0.08 0.06-0.10 0.06-0.12 0.08-0.14 0.10-0.16

Martensitic 820 240 13

M Stainless steel and cast steel Austenitic 600 180 14 25-45 0.04-0.08 0.06-0.10 0.06-0.12 0.08-0.14 0.10-0.16

Ferritic/pearlitic 180 15

Grey cast iron (GG) 60-70

Pearlitic 260 16

Ferritic 160 17

K Cast iron nodular (GGG) 55-65 0.10-0.18 0.12-0.20 0.14-0.22 0.14-0.24 0.16-0.26

Pearlitic 250 18

Ferritic 130 19

Malleable cast iron 50-60

Pearlitic 230 20

Annealed 200 31

Fe based 30-35 0.04-0.08 0.06-0.10 0.06-0.12 0.08-0.14 0.10-.0.16

Cured 280 32

High temp. alloys Annealed 250 33

Ni or Co

S based Cured 350 34 25-30 0.04-0.08 0.06-0.10 0.06-0.12 0.08-0.14 0.10-.0.16

Cast 320 35

Pure RM 400 110 36

Titanium Ti alloys Alpha+beta 30-35 0.04-0.08 0.06-0.10 0.06-0.12 0.08-0.14 0.10-.0.16

alloys cured RM 1050 310 37

222 ISCAR