Page 105 - HOLE_MAKING_CATALOG_INCH_2022_P447-P626

P. 105

USER GUIDE

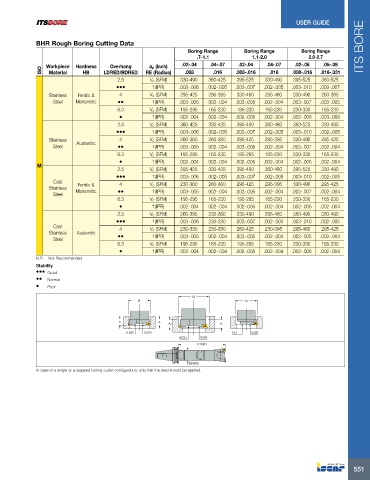

BHR Rough Boring Cutting Data

Boring Range Boring Range Boring Range ITS BORE

.7-1.1 1.1-2.0 2.0-2.7

Workpiece Hardness Overhang ap (inch) .02-.04 .04-.07 .02-.04 .04-.07 .02-.06 .05-.08

ISO Material HB LDRED/BDRED RE (Radius) .008 .016 .008-.016 .016 .008-.016 .016-.031

2.5 Vc (SFM) 330-490 360-425 395-525 330-490 395-525 360-525

••• f (IPR) .003-.006 .002-.005 .003-.007 .002-.005 .003-.010 .003-.007

Stainless Ferritic & 4 Vc (SFM) 295-425 295-395 330-460 295-460 330-490 260-395

Steel Martensitic •• f (IPR) .003-.005 .002-.004 .003-.005 .002-.004 .003-.007 .003-.005

6.3 Vc (SFM) 195-295 165-230 195-230 165-230 230-330 165-230

• f (IPR) .002-.004 .002-.004 .002-.005 .002-.004 .002-.006 .003-.006

2.5 Vc (SFM) 360-425 330-425 395-490 360-460 360-525 330-490

••• f (IPR) .003-.006 .002-.005 .003-.007 .002-.005 .003-.010 .002-.005

Stainless Austenitic 4 Vc (SFM) 260-360 260-360 295-425 295-395 330-490 295-425

Steel •• f (IPR) .003-.005 .002-.004 .003-.005 .002-.004 .003-.007 .002-.004

6.3 Vc (SFM) 195-295 165-230 195-295 165-230 230-330 165-230

• f (IPR) .002-.004 .002-.004 .002-.005 .002-.004 .002-.006 .002-.004

M

2.5 Vc (SFM) 295-425 330-425 395-490 360-460 395-525 330-490

••• f (IPR) .003-.006 .002-.005 .003-.007 .002-.005 .003-.010 .002-.005

Cast 4 Vc (SFM) 230-360 260-360 295-425 295-395 330-490 295-425

Ferritic &

Stainless Martensitic

Steel •• f (IPR) .003-.005 .002-.004 .003-.005 .002-.004 .003-.007 .002-.004

6.3 Vc (SFM) 195-295 165-230 195-295 165-230 230-330 165-230

• f (IPR) .002-.004 .002-.004 .002-.005 .002-.004 .002-.006 .002-.004

2.5 Vc (SFM) 260-395 230-360 330-490 295-460 360-490 330-490

••• f (IPR) .003-.006 230-330 .003-.007 .002-.005 .003-.010 .002-.005

Cast 4 Vc (SFM) 230-330 230-330 260-425 230-395 295-460 295-425

Stainless Austenitic ••

Steel f (IPR) .003-.005 .002-.004 .003-.005 .002-.004 .003-.005 .002-.004

6.3 Vc (SFM) 195-295 165-230 195-295 165-230 230-330 165-230

• f (IPR) .002-.004 .002-.004 .002-.005 .002-.004 .002-.006 .002-.004

N.R. = Not Recommended

Stability

••• Good

•• Normal

• Poor

Ø

Ø Ø

A A

A1 A

IHSR

IHSR IHSR PLT IHSR

IHCR IHSR

LDRED

BDRED

In case of a single or a stepped boring cutter configuration, only half the feed should be applied.

551