Page 108 - HOLE_MAKING_CATALOG_INCH_2022_P447-P626

P. 108

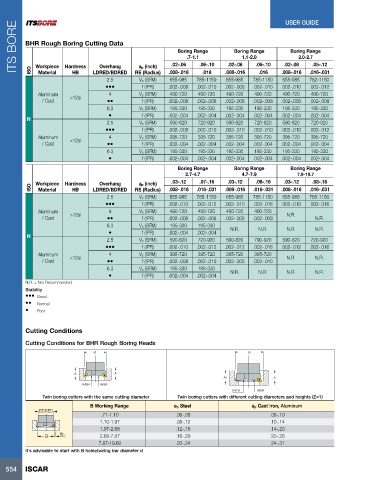

ITS BORE BHR Rough Boring Cutting Data Boring Range Boring Range USER GUIDE

Boring Range

.7-1.1

2.0-2.7

1.1-2.0

.02-.08

.06-.10

.05-.12

.06-.10

.02-.06

.02-.06

Workpiece Hardness

ap (inch)

Overhang

ISO

Material

HB

.016

.016

LDRED/BDRED

.016-.031

2.5 RE (Radius) .008-.016 785-1150 .008-.016 785-1150 .008-.016 782-1150

655-985

Vc (SFM)

655-985

655-985

••• f (IPR) .002-.008 .002-.010 .002-.008 .002-.010 .002-.010 .002-.012

Aluminum 4 Vc (SFM) 490-720 490-720 490-720 490-720 490-720 490-720

/ Cast >12si •• f (IPR) .002-.008 .002-.008 .002-.008 .002-.008 .002-.008 .002-.008

6.3 Vc (SFM) 195-330 195-330 195-330 195-330 195-330 195-330

• f (IPR) .002-.004 .002-.004 .002-.004 .002-.004 .002-.004 .002-.004

N

2.5 Vc (SFM) 590-820 720-920 590-820 720-920 590-820 720-920

••• f (IPR) .002-.008 .002-.010 .002-.010 .002-.010 .002-.010 .002-.012

Aluminum 4 Vc (SFM) 395-720 395-720 395-720 395-720 395-720 395-720

/ Cast <12si •• f (IPR) .002-.004 .002-.004 .002-.004 .002-.004 .002-.004 .002-.004

6.3 Vc (SFM) 195-330 195-330 195-330 195-330 195-330 195-330

• f (IPR) .002-.004 .002-.004 .002-.004 .002-.004 .002-.004 .002-.004

Boring Range Boring Range Boring Range

2.7-4.7 4.7-7.9 7.9-19.7

Workpiece Hardness Overhang ap (inch) .03-.12 .07-.16 .03-.12 .08-.16 .03-.12 .08-.18

ISO Material HB LDRED/BDRED RE (Radius) .008-.016 .016-.031 .008-.016 .016-.031 .008-.016 .016-.031

2.5 Vc (SFM) 655-985 785-1150 655-985 785-1150 655-985 785-1150

••• f (IPR) .002-.010 .002-.012 .002-.010 .002-.016 .002-.010 .002-.016

Aluminum >12si 4 Vc (SFM) 490-720 490-720 490-720 490-720 N.R.

/ Cast •• f (IPR) .002-.008 .002-.008 .002-.008 .002-.008 N.R.

6.3 Vc (SFM) 195-330 195-330

• f (IPR) .002-.004 .002-.004 N.R. N.R. N.R. N.R.

N

2.5 Vc (SFM) 590-820 720-920 590-820 790-920 590-820 720-920

••• f (IPR) .002-.010 .002-.012 .002-.012 .002-.016 .002-.012 .002-.016

Aluminum <12si 4 Vc (SFM) 395-720 395-720 395-720 395-720 N.R. N.R.

/ Cast •• f (IPR) .002-.008 .002-.010 .002-.008 .002-.010

6.3 Vc (SFM) 195-330 195-330

• f (IPR) .002-.004 .002-.004 N.R. N.R. N.R. N.R.

N.R. = Not Recommended

Stability

••• Good

•• Normal

• Poor

Cutting Conditions

Cutting Conditions for BHR Rough Boring Heads

Ø Ø

A A

A1 A

IHSR

IHSR IHSR

IHCR IHSR

Twin boring cutters with the same cutting diameter Twin boring cutters with different cutting diameters and heights (Z=1)

B Working Range ap Steel ap Cast Iron, Aluminum

BDRED

.71-1.10 .06-.08 .08-.10

1.10-1.97 .08-.12 .10-.14

1.97-2.68 .12-.16 .14-.20

B ap 2.68-7.87 .16-.20 .20-.28

7.87-19.69 .20-.24 .24-.31

It’s advisable to start with B hole≥boring bar diameter d

554 ISCAR