Page 26 - MILLING_CATALOG_INCH_2022_P1-P92

P. 26

DRVS

ENDMILLS • SOLID CARBIDE • MULTI-MASTER

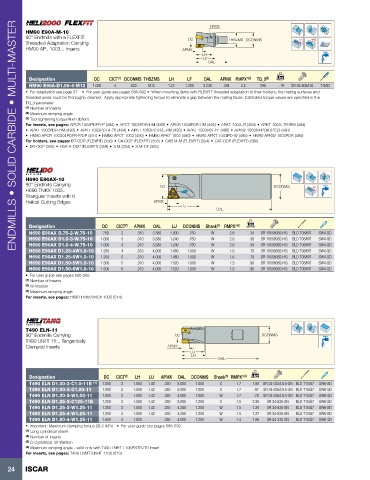

HM90 E90A-M-10

90° Endmills with a FLEXFIT DC THSZMS DCONMS

Threaded Adaptation Carrying Rd°

HM90 AP.. 1003... Inserts APMX

LH

LF

OAL

Designation DC CICT (1) DCONMS THSZMS LH LF OAL APMX RMPX° (2) TQ_3 (3) Lbs

HM90 E90A-D1.00-4-M12 1.000 4 .830 M12 1.22 1.380 2.240 .394 2.5 295 .19 SR 34-505/HG T-8/53

• For adaptation see page 37 • For user guide see pages 586-592 • When mounting items with FLEXFIT threaded adaptation to their holders, the mating surfaces and

threaded areas must be thoroughly cleaned. Apply appropriate tightening torque to eliminate a gap between the mating faces. Estimated torque values are specified in the

TQ_3 parameter

(1) Number of inserts

(2) Maximum ramping angle

(3) Tool tightening torque Nxm (lbfxin)

For inserts, see pages: APCR 1003PDFR-P (492) • APCT 1003PDR-HM (492) • APKR 1003PDR-HM (492) • APKT 1003..R (494) • APKT 1003..TR-RM (494)

• APKT 1003PDR-HM (493) • APKT 1003PDTR-76 (494) • APKT 1003PDTR/L-RM (493) • APKT 1003R8T-FF (496) • APKW 100304 PDR (PCD) (491)

• HM90 APCR 100304PDFR-P/DP (491) • HM90 APCT 1003 (490) • HM90 APKT 1003 (490) • HM90 APKT 1003PD-W (495) • HM90 APKW 1003PDR (495)

For holders, see pages: BT-ODP (FLEXFIT) (356) • C#-ODP (FLEXFIT) (356) • CAB M-M (FLEXFIT) (354) • CAT-ODP (FLEXFIT) (360)

• ER-ODP (358) • HSK A-ODP (FLEXFIT) (359) • S M (354) • S M-CF (355)

H690 E90AX-10

90° Endmills Carrying DC DCONMS

H690 TNKX 1005.. Rd°

Triangular Inserts with 6

Helical Cutting Edges APMX

LU

OAL

Designation DC CICT (1) APMX OAL LU DCONMS Shank (2) RMPX° (3) Lbs

H690 E90AX D.75-2-W.75-10 .750 2 .310 3.380 1.000 .750 W 2.8 .34 SR 10508082-HG BLD T08/M7 SW4-SD

H690 E90AX D1.0-3-W.75-10 1.000 3 .310 3.380 1.240 .750 W 2.6 .38 SR 10508082-HG BLD T08/M7 SW4-SD

H690 E90AX D1.0-4-W.75-10 1.000 4 .310 3.380 1.240 .750 W 2.6 .39 SR 10508082-HG BLD T08/M7 SW4-SD

H690 E90AX D1.25-4W1.0-10 1.250 4 .310 4.000 1.480 1.000 W 1.6 .79 SR 10508082-HG BLD T08/M7 SW4-SD

H690 E90AX D1.25-5W1.0-10 1.250 5 .310 4.000 1.480 1.000 W 1.6 .79 SR 10508082-HG BLD T08/M7 SW4-SD

H690 E90AX D1.50-5W1.0-10 1.500 5 .310 4.000 1.520 1.000 W 1.3 .90 SR 10508082-HG BLD T08/M7 SW4-SD

H690 E90AX D1.50-6W1.0-10 1.500 6 .310 4.000 1.520 1.000 W 1.3 .90 SR 10508082-HG BLD T08/M7 SW4-SD

• For user guide see pages 586-592

(1) Number of inserts

(2) W-Weldon

(3) Maximum ramping angle

For inserts, see pages: H690 TNKX/TNCX 1005 (514)

T490 ELN-11

90° Endmills Carrying DC DCONMS

T490 LN#T 11... Tangentially

Clamped Inserts APMX

LU

LH

OAL

Designation DC CICT (2) LH LU APMX OAL DCONMS Shank (3) RMPX° (4) Lbs

T490 ELN D1.00-3-C1.0-11B (1) 1.000 3 1.500 1.42 .350 8.000 1.000 C 1.7 1.60 SR 34-535/L9.5-SN BLD T15/S7 SW6-SD

T490 ELN D1.00-3-C1.00-11 1.000 3 1.500 1.42 .350 5.000 1.000 C 1.7 .97 SR 34-535/L9.5-SN BLD T15/S7 SW6-SD

T490 ELN D1.00-3-W1.00-11 1.000 3 1.500 1.42 .350 4.000 1.000 W 1.7 .76 SR 34-535/L9.5-SN BLD T15/S7 SW6-SD

T490 ELN D1.25-3-C125-11B 1.250 3 1.500 1.42 .350 8.000 1.250 C 1.5 3.38 SR 34-535-SN BLD T15/S7 SW6-SD

T490 ELN D1.25-3-W1.25-11 1.250 3 1.500 1.42 .350 4.250 1.250 W 1.5 1.28 SR 34-535-SN BLD T15/S7 SW6-SD

T490 ELN D1.25-4-W1.25-11 1.250 4 1.500 1.42 .350 4.250 1.250 W 1.5 1.27 SR 34-535-SN BLD T15/S7 SW6-SD

T490 ELN D1.50-4-W1.25-11 1.500 4 1.620 - .350 4.500 1.250 W 1.4 1.56 SR 34-535-SN BLD T15/S7 SW6-SD

• Important: Maximum clamping torque 28.3 lbf*in • For user guide see pages 586-592

(1) Long cylindrical shank

(2) Number of inserts

(3) C-Cylindrical, W-Weldon

(4) Maximum ramping angle - valid only with T490 LNHT 1106PNTR-RD insert

For inserts, see pages: T490 LNMT/LNHT 1106 (519)

24 ISCAR