Page 115 - MILLING_CATALOG_INCH_2022_P229-P360

P. 115

LF OAL

FFQ4 D-M-09 DCX DC THSZMS DCONMS Rd°

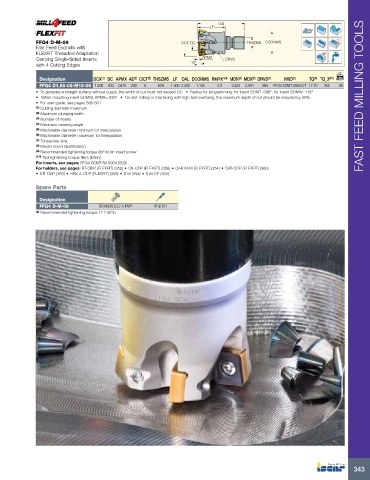

Fast Feed Endmills with

FLEXFIT Threaded Adaptation

Carrying Single-Sided Inserts APMX DRVS

with 4 Cutting Edges 12˚

Designation DCX (1) DC APMX AE (2) CICT (3) THSZMS LF OAL DCONMS RMPX° (4) MDN (5) MDX (6) DRVS (7) MIID (8) TQ (9) TQ_3 (10) Lbs

FFQ4 D1.50-05-M16-09 1.500 .933 .0470 .280 5 M16 1.400 2.400 1.142 2.3 2.433 2.961 .984 FFQ4 SOMT 090412T 17.70 355 .39

• To generate a straight surface without cusps, the width of cut must not exceed DC • Radius for programming: for insert SOMT .098", for insert SOMW .118"

• When mounting insert SOMW, APMX=.039" • For slot milling or machining with high tool overhang, the maximum depth of cut should be reduced by 50% FAST FEED MILLING TOOLS

• For user guide, see pages 586-591

(1) Cutting diameter maximum

(2) Maximum plunging width

(3) Number of inserts

(4) Maximum ramping angle

(5) Machinable diameter minimum for interpolation

(6) Machinable diameter maximum for interpolation

(7) Torque key size

(8) Master insert identification

(9) Recommended tightening torque (lbf*in) for insert screw

(10) Tool tightening torque Nxm (lbfxin)

For inserts, see pages: FFQ4 SOMT/W 0904 (559)

For holders, see pages: BT-ODP (FLEXFIT) (356) • C#-ODP (FLEXFIT) (356) • CAB M-M (FLEXFIT) (354) • CAT-ODP (FLEXFIT) (360)

• ER-ODP (358) • HSK A-ODP (FLEXFIT) (359) • S M (354) • S M-CF (355)

Spare Parts

Designation

FFQ4 D-M-09 SR M3X0.5-L7.4 IP9 (a) IP-9/151

(a) Recommended tightening torque:17.7 lbf*in

343