Page 64 - MILLING_CATALOG_INCH_2022_P229-P360

P. 64

PLUNGING CUTTERS

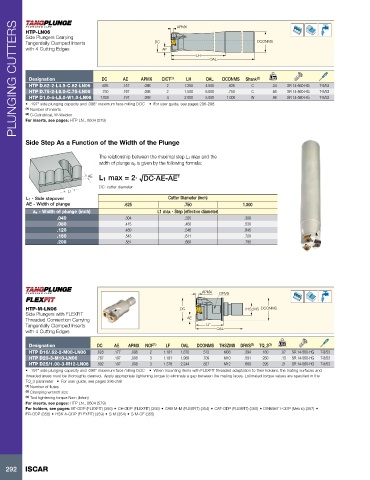

HTP-LN06 APMX

Side Plungers Carrying

Tangentially Clamped Inserts DC DCONMS

with 4 Cutting Edges AE

LH

OAL

Designation DC AE APMX CICT (1) LH OAL DCONMS Shank (2) Lbs

HTP D.62-2-L4.5-C.62-LN06 .625 .157 .098 2 1.250 4.500 .625 C .34 SR 14-560-HG T-8/53

HTP D.75-2-L6.0-C.75-LN06 .750 .197 .098 2 1.500 6.000 .750 C .68 SR 14-560-HG T-8/53

HTP D1.0-4-L5.0-W1.0-LN06 1.000 .197 .098 4 2.000 5.000 1.000 W .96 SR 14-560-HG T-8/53

• .197" side plunging capacity and .098" maximum face milling DOC • For user guide, see pages 296-298

(1) Number of inserts

(2) C-Cylindrical, W-Weldon

For inserts, see pages: HTP LN.. 0604 (579)

Side Step As a Function of the Width of the Plunge

The relationship between the maximal step L1 max and the

width of plunge ae is given by the following formula:

AE L1 max = 2∙ √DC∙AE-AE ²

DC: cutter diameter

L1

L1 - Side stepover Cutter Diameter (inch)

AE - Width of plunge .625 .750 1.000

ae - Width of plunge (inch) L1 max - Step (effective diameter)

.040 .304 .335 .389

.080 .415 .460 .539

.120 .489 .546 .645

.160 .543 .611 .729

.200 .581 .660 .795

APMX DRVS

HTP-M-LN06 DC THSZMS DCONMS

Side Plungers with FLEXFIT

Threaded Connection Carrying AE

Tangentially Clamped Inserts LF

with 4 Cutting Edges OAL

Designation DC AE APMX NOF (1) LF OAL DCONMS THSZMS DRVS (2) TQ_3 (3) Lbs

HTP D16/.62-2-M08-LN06 .628 .177 .098 2 1.181 1.870 .512 M08 .394 180 .07 SR 14-560-HG T-8/53

HTP D20-3-M10-LN06 .787 .197 .098 3 1.181 1.968 .709 M10 .591 260 .13 SR 14-560-HG T-8/53

HTP D25/1.00-3-M12-LN06 .992 .197 .098 3 1.378 2.244 .827 M12 .669 295 .21 SR 14-560-HG T-8/53

• .197" side plunging capacity and .098" maximum face milling DOC • When mounting items with FLEXFIT threaded adaptation to their holders, the mating surfaces and

threaded areas must be thoroughly cleaned. Apply appropriate tightening torque to eliminate a gap between the mating faces. Estimated torque values are specified in the

TQ_3 parameter • For user guide, see pages 296-298

(1) Number of flutes

(2) Clamping wrench size

(3) Tool tightening torque Nxm (lbfxin)

For inserts, see pages: HTP LN.. 0604 (579)

For holders, see pages: BT-ODP (FLEXFIT) (356) • C#-ODP (FLEXFIT) (356) • CAB M-M (FLEXFIT) (354) • CAT-ODP (FLEXFIT) (360) • DIN69871-ODP (Metric) (357) •

ER-ODP (358) • HSK A-ODP (FLEXFIT) (359) • S M (354) • S M-CF (355)

292 ISCAR