Page 82 - MILLING_CATALOG_INCH_2022_P229-P360

P. 82

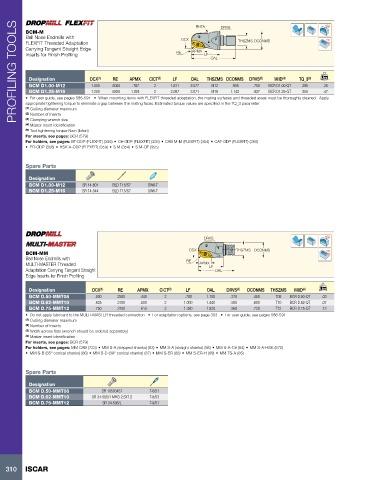

PROFILING TOOLS BCM-M DCX (1) .5000 APMX CICT (2) 1.811 RE DCX 2.677 LF THSZMS DCONMS DRVS (3) BCR D1.00-QT TQ_3 (5) Lbs Rd°

BHTA

DRVS

Ball Nose Endmills with

THSZMS

DCONMS

FLEXFIT Threaded Adaptation

Carrying Tangent Straight Edge

APMX

Inserts for Finish Profiling

OAL

(4)

OAL

LF

RE

MIID

Designation

BCM D1.00-M12

.905

295

.26

M12

.787

2

.750

1.000

BCM D1.25-M16

1.142

2

2.087

3.071

1.024

M16

1.250

.6250

.937

BCR D1.25-QT

355

.47

• For user guide, see pages 586-591 • When mounting items with FLEXFIT threaded adaptation, the mating surfaces and threaded areas must be thoroughly cleaned. Apply

appropriate tightening torque to eliminate a gap between the mating faces. Estimated torque values are specified in the TQ_3 parameter

(1) Cutting diameter maximum

(2) Number of inserts

(3) Clamping wrench size

(4) Master insert identification

(5) Tool tightening torque Nxm (lbfxin)

For inserts, see pages: BCR (579)

For holders, see pages: BT-ODP (FLEXFIT) (356) • C#-ODP (FLEXFIT) (356) • CAB M-M (FLEXFIT) (354) • CAT-ODP (FLEXFIT) (360)

• ER-ODP (358) • HSK A-ODP (FLEXFIT) (359) • S M (354) • S M-CF (355)

Spare Parts

Designation

BCM D1.00-M12 SR 14-601 BLD T15/S7 SW6-T

BCM D1.25-M16 SR 14-544 BLD T15/S7 SW6-T

DRVS

BCM-MM DCX THSZMS DCONMS Rd°

Ball Nose Endmills with RE

MULTI-MASTER Threaded APMX LF

Adaptation Carrying Tangent Straight OAL

Edge Inserts for Finish Profiling

Designation DCX (1) RE APMX CICT (2) LF OAL DRVS (3) DCONMS THSZMS MIID (4) Lbs

BCM D.50-MMT08 .500 .2500 .440 2 .780 1.100 .370 .450 T08 BCR D.50-QT .03

BCM D.62-MMT10 .625 .3100 .500 2 1.000 1.440 .500 .600 T10 BCR D.62-QT .07

BCM D.75-MMT12 .750 .3700 .610 2 1.380 1.920 .560 .720 T12 BCR D.75-QT .13

• Do not apply lubricant to the MULTI-MASTER threaded connection • For adaptation options, see page 303 • For user guide, see pages 586-591

(1) Cutting diameter maximum

(2) Number of inserts

(3) Width across flats (wrench should be ordered separately)

(4) Master insert identification

For inserts, see pages: BCR (579)

For holders, see pages: MM CAB (733) • MM S-A (stepped shanks) (83) • MM S-A (straight shanks) (86) • MM S-A-C# (84) • MM S-A-HSK (672)

• MM S-B (85° conical shanks) (86) • MM S-D (89° conical shanks) (87) • MM S-ER (88) • MM S-ER-H (89) • MM TS-A (85)

Spare Parts

Designation

BCM D.50-MMT08 SR 10503457 T-6/51

BCM D.62-MMT10 SR 34-505/1 MHG 2.5X7.2 T-8/53

BCM D.75-MMT12 SR 34-506/L T-9/51

310 ISCAR