Page 45 - Turning_catalog_INCH_2022_45_P261-508

P. 45

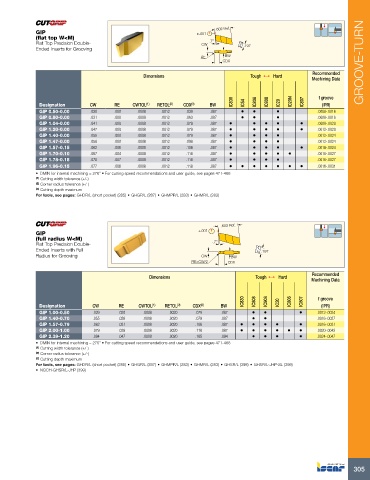

GIP ±.001 .602 Ref.

(flat top W<M)

Flat Top Precision Double- CW 7° .197

Ended Inserts for Grooving

RE BW

CDX GROOVE-TURN

Dimensions Tough 1 Hard Recommended

Machining Data

IC830 IC808 IC908 IC20N IC807 f groove

Designation CW RE CWTOL (1) RETOL (2) CDX (3) BW IC54 IC20 (IPR)

GIP 0.50-0.00 .020 .000 .0008 .0012 .039 .087 • • • .0008-.0016

GIP 0.80-0.00 .031 .000 .0008 .0012 .063 .087 • • • .0008-.0016

GIP 1.04-0.00 .041 .000 .0008 .0012 .079 .087 • • • • • .0008-.0020

GIP 1.20-0.00 .047 .000 .0008 .0012 .079 .087 • • • • • .0012-.0020

GIP 1.40-0.00 .055 .000 .0008 .0012 .079 .087 • • • • .0012-.0024

GIP 1.47-0.00 .058 .000 .0008 .0012 .098 .087 • • • • .0012-.0024

GIP 1.57-0.15 .062 .006 .0008 .0012 .106 .087 • • • • • .0016-.0024

GIP 1.70-0.10 .067 .004 .0008 .0012 .118 .087 • • • • • .0016-.0027

GIP 1.78-0.18 .070 .007 .0008 .0012 .118 .087 • • • • .0016-.0027

GIP 1.96-0.15 .077 .006 .0008 .0012 .118 .087 • • • • • • • .0016-.0031

• DMIN for internal machining = 276" • For cutting speed recommendations and user guide, see pages 471-488

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Cutting depth maximum

For tools, see pages: GHDR/L (short pocket) (285) • GHGR/L (287) • GHMPR/L (283) • GHMR/L (283)

.602 Ref.

GIP ±.001

(full radius W<M)

Flat Top Precision Double- 7°

Ended Inserts with Full .197

Radius for Grooving CW BW

RE=CW/2 CDX

Recommended

Dimensions Tough 1 Hard

Machining Data

IC830 IC808 IC908 IC20 IC806 IC807 f groove

Designation CW RE CWTOL (1) RETOL (2) CDX (3) BW (IPR)

GIP 1.00-0.50 .039 .020 .0008 .0020 .079 .087 • • • .0012-.0024

GIP 1.40-0.70 .055 .028 .0008 .0020 .079 .087 • • .0016-.0027

GIP 1.57-0.79 .062 .031 .0008 .0020 .106 .087 • • • • • .0016-.0031

GIP 2.00-1.00 .079 .039 .0008 .0020 .118 .087 • • • • • • .0020-.0043

GIP 2.39-1.20 .094 .047 .0008 .0020 .185 .094 • • • • .0024-.0047

• DMIN for internal machining = 276" • For cutting speed recommendations and user guide, see pages 471-488

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Cutting depth maximum

For tools, see pages: GHDR/L (short pocket) (285) • GHGR/L (287) • GHMPR/L (283) • GHMR/L (283) • GHSR/L (398) • GHSR/L-JHP-SL (399)

• NQCH-GHSR/L-JHP (399)

305