Page 48 - Turning_catalog_INCH_2022_45_P261-508

P. 48

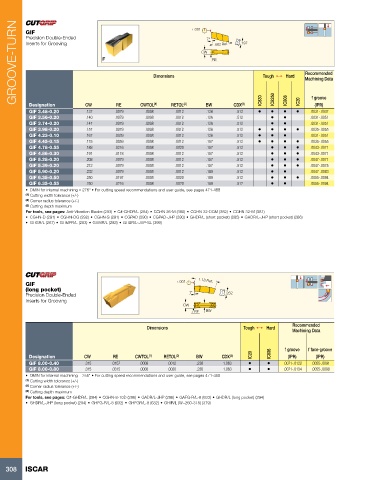

GROOVE-TURN GIF Dimensions ±.001 CW 7° RE .602 Ref. .197 Tough 1 Hard Recommended

Precision Double-Ended

Inserts for Grooving

Machining Data

f groove

CW

RE

BW

(IPR)

Designation

GIF 3.48-0.20 .137 .0079 CWTOL (1) RETOL (2) .126 CDX (3) • IC830 • IC8250 • IC808 • IC20 .0031-.0047

.0012

.512

.0008

GIF 3.56-0.20 .140 .0079 .0008 .0012 .126 .512 • • .0031-.0051

GIF 3.74-0.20 .147 .0079 .0008 .0012 .126 .512 • • .0031-.0051

GIF 3.98-0.20 .157 .0079 .0008 .0012 .126 .512 • • • • .0035-.0055

GIF 4.23-0.10 .167 .0039 .0008 .0012 .126 .512 • • • .0031-.0051

GIF 4.45-0.15 .175 .0059 .0008 .0012 .157 .512 • • • • .0035-.0055

GIF 4.78-0.55 .188 .0216 .0008 .0020 .157 .512 • • • .0043-.0071

GIF 4.86-0.30 .191 .0118 .0008 .0012 .157 .512 • • • .0043-.0071

GIF 5.28-0.20 .208 .0079 .0008 .0012 .157 .512 • • • .0047-.0071

GIF 5.39-0.20 .212 .0079 .0008 .0012 .157 .512 • • • .0047-.0075

GIF 5.90-0.20 .232 .0079 .0008 .0012 .189 .512 • • .0047-.0083

GIF 6.35-0.50 .250 .0197 .0008 .0020 .189 .512 • • • .0055-.0094

GIF 6.35-0.55 .250 .0216 .0008 .0020 .189 .512 • • .0055-.0094

• DMIN for internal machining = 276" • For cutting speed recommendations and user guide, see pages 471-488

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Cutting depth maximum

For tools, see pages: Anti-Vibration Blades (293) • C#-GHDR/L (284) • CGHN 26-M (380) • CGHN 32-DGM (382) • CGHN 32-M (381)

• CGHN-D (291) • CGHN-DG (292) • CGHN-S (291) • CGPAD (290) • CGPAD-JHP (290) • GHDR/L (short pocket) (285) • GHDR/L-JHP (short pocket) (286)

• GHGR/L (287) • GHMPR/L (283) • GHMR/L (283) • GHSR/L-JHP-SL (399)

GIF ±.001 1.18 Ref.

(long pocket)

Precision Double-Ended 7˚ .252

Inserts for Grooving

CW

RE BW

Recommended

Dimensions Tough 1 Hard Machining Data

Designation CW RE CWTOL (1) RETOL (2) BW CDX (3) IC20 IC806 f groove f face-groove

(IPR)

(IPR)

GIF 8.00-0.40 .315 .0157 .0008 .0012 .236 1.063 • • .0071-.0122 .0055-.0091

GIF 8.00-0.80 .315 .0315 .0008 .0020 .236 1.063 • • .0071-.0134 .0055-.0098

• DMIN for internal machining = 256" • For cutting speed recommendations and user guide, see pages 471-488

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Cutting depth maximum

For tools, see pages: C#-GHDR/L (284) • CGHN-8-10D (296) • GADR/L-JHP (296) • GAFG-R/L-8 (633) • GHDR/L (long pocket) (294)

• GHDR/L-JHP (long pocket) (294) • GHFG-R/L-8 (632) • GHFGR/L-8 (632) • GHIR/L (W=260-315) (379)

308 ISCAR