Page 79 - Turning_catalog_INCH_2022_45_P261-508

P. 79

CW ±.0016

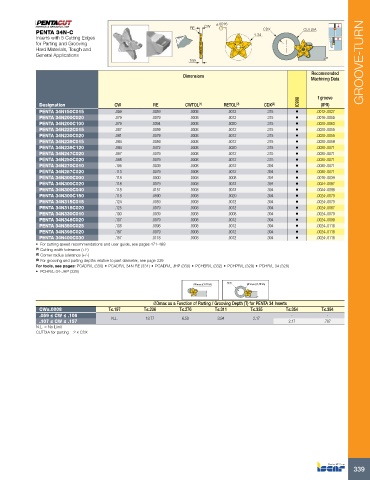

PENTA 34N-C RE CDX CUTDIA

Inserts with 5 Cutting Edges 1.34

for Parting and Grooving

Hard Materials, Tough and

General Applications

.169 GROOVE-TURN

Dimensions Recommended

Machining Data

IC908 f groove

Designation CW RE CWTOL (1) RETOL (2) CDX (3) (IPR)

PENTA 34N150C015 .059 .0059 .0008 .0012 .315 • .0012-.0027

PENTA 34N200C020 .079 .0079 .0008 .0012 .315 • .0016-.0055

PENTA 34N200C100 .079 .0394 .0008 .0020 .315 • .0020-.0063

PENTA 34N222C015 .087 .0059 .0008 .0012 .315 • .0020-.0055

PENTA 34N230C020 .091 .0079 .0008 .0012 .315 • .0020-.0055

PENTA 34N239C015 .094 .0059 .0008 .0012 .315 • .0020-.0059

PENTA 34N239C120 .094 .0472 .0008 .0020 .315 • .0020-.0071

PENTA 34N247C020 .097 .0079 .0008 .0012 .315 • .0020-.0071

PENTA 34N250C020 .098 .0079 .0008 .0012 .315 • .0020-.0071

PENTA 34N270C010 .106 .0039 .0008 .0012 .394 • .0020-.0071

PENTA 34N287C020 .113 .0079 .0008 .0012 .394 • .0020-.0071

PENTA 34N300C000 .118 .0000 .0008 .0008 .394 • .0016-.0039

PENTA 34N300C020 .118 .0079 .0008 .0012 .394 • .0024-.0087

PENTA 34N300C040 .118 .0157 .0008 .0012 .394 • .0024-.0098

PENTA 34N300C150 .118 .0590 .0008 .0020 .394 • .0024-.0079

PENTA 34N315C015 .124 .0059 .0008 .0012 .394 • .0024-.0079

PENTA 34N318C020 .125 .0079 .0008 .0012 .394 • .0024-.0087

PENTA 34N330C010 .130 .0039 .0008 .0008 .394 • .0024-.0079

PENTA 34N348C020 .137 .0079 .0008 .0012 .394 • .0024-.0098

PENTA 34N350C025 .138 .0098 .0008 .0012 .394 • .0024-.0118

PENTA 34N398C020 .157 .0079 .0008 .0012 .394 • .0024-.0118

PENTA 34N400C030 .157 .0118 .0008 .0012 .394 • .0024-.0118

• For cutting speed recommendations and user guide, see pages 471-488

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) For grooving and parting depths relative to part diameter, see page 339

For tools, see pages: PCADR/L (330) • PCADR/L 34N-RE (331) • PCADR/L-JHP (330) • PCHBR/L (332) • PCHPR/L (329) • PCHR/L-34 (328)

• PCHR/L-34-JHP (328)

CDX

ØDmax (CUTDIA) ØDmax (CUTDIA)

ØDmax as a Function of Parting / Grooving Depth (T) for PENTA 34 Inserts

CW±.0008 T≤.197 T≤.236 T≤.276 T≤.311 T≤.335 T≤.354 T≤.394

.059 ≤ CW ≤ .106 - -

.107 ≤ CW ≤ .157 N.L. 13.77 6.50 3.94 2.17 2.17 .787

N.L. = No Limit

CUTDIA for parting = 2 x CDX

339