Page 69 - Turning_catalog_INCH_2022_45_P509-690

P. 69

±.004

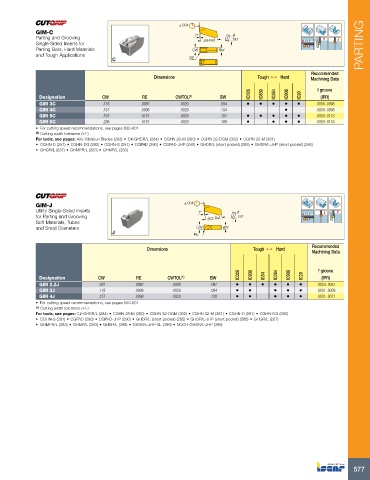

GIM-C

Parting and Grooving 7° .59 Ref. .197

Single-Sided Inserts for PARTING

Parting Bars, Hard Materials CW BW

and Tough Applications

RE

Recommended

Dimensions Tough 1 Hard Machining Data

IC328 IC830 IC354 IC908 f groove

Designation CW RE CWTOL (1) BW IC20 (IPR)

GIM 3C .118 .0087 .0020 .094 • • • • • .0059-.0098

GIM 4C .157 .0098 .0020 .134 • .0059-.0098

GIM 5C .197 .0157 .0020 .157 • • • • • .0059-.0118

GIM 6C .236 .0157 .0020 .189 • • • • .0059-.0118

• For cutting speed recommendations, see pages 600-601

(1) Cutting width tolerance (+/-)

For tools, see pages: Anti-Vibration Blades (293) • C#-GHDR/L (284) • CGHN 26-M (380) • CGHN 32-DGM (382) • CGHN 32-M (381)

• CGHN-D (291) • CGHN-DG (292) • CGHN-S (291) • CGPAD (290) • CGPAD-JHP (290) • GHDR/L (short pocket) (285) • GHDR/L-JHP (short pocket) (286)

• GHGR/L (287) • GHMPR/L (283) • GHMR/L (283)

GIM-J ±.004

Utility Single-Sided Inserts 7°

for Parting and Grooving .602 Ref. .197

Soft Materials, Tubes

and Small Diameters CW BW

RE

Recommended

Dimensions Tough 1 Hard Machining Data

IC328 IC830 IC54 IC354 IC908 IC20 f groove

Designation CW RE CWTOL (1) BW (IPR)

GIM 2.2J .087 .0067 .0020 .067 • • • • • • .0024-.0051

GIM 3J .118 .0098 .0020 .094 • • • • • .0031-.0059

GIM 4J .157 .0098 .0020 .126 • • • • • .0031-.0071

• For cutting speed recommendations, see pages 600-601

(1) Cutting width tolerance (+/-)

For tools, see pages: C#-GHDR/L (284) • CGHN 26-M (380) • CGHN 32-DGM (382) • CGHN 32-M (381) • CGHN-D (291) • CGHN-DG (292)

• CGHN-S (291) • CGPAD (290) • CGPAD-JHP (290) • GHDR/L (short pocket) (285) • GHDR/L-JHP (short pocket) (286) • GHGR/L (287)

• GHMPR/L (283) • GHMR/L (283) • GHSR/L (398) • GHSR/L-JHP-SL (399) • NQCH-GHSR/L-JHP (399)

577