Page 90 - Turning_catalog_INCH_2022_45_P509-690

P. 90

PARTING PARTING USER GUIDE

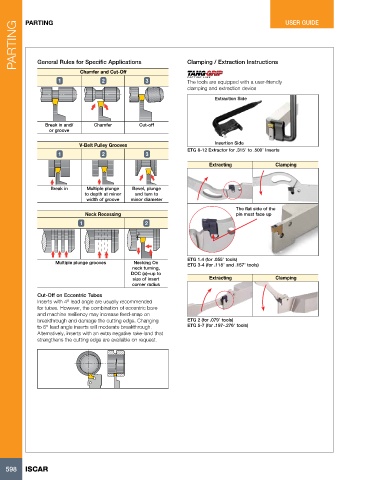

General Rules for Specific Applications

Chamfer and Cut-Off Clamping / Extraction Instructions

1 2 3 The tools are equipped with a user-friendly

clamping and extraction device

Extraction Side

Break in and/ Chamfer Cut-off

or groove

V-Belt Pulley Grooves Insertion Side

ETG 8-12 Extractor for .315” to .500” Inserts

1 2 3

Extracting Clamping

Break in Multiple plunge Bevel, plunge

to depth at minor and turn to

width of groove minor diameter

The flat side of the

Neck Recessing pin must face up

1 2

a

ETG 1.4 (for .055” tools)

Multiple plunge grooves Necking On ETG 3-4 (for .118” and .157” tools)

neck turning,

DOC (a)=up to

size of insert Extracting Clamping

corner radius

Cut-Off on Eccentric Tubes

Inserts with 4º lead angle are usually recommended

for tubes. However, the combination of eccentric bore

and machine resiliency may increase feed-snap on

breakthrough and damage the cutting edge. Changing ETG 2 (for .079” tools)

to 6º lead angle inserts will moderate breakthrough. ETG 5-7 (for .197-.276” tools)

Alternatively, inserts with an extra negative rake-land that

strengthens the cutting edge are available on request.

598 ISCAR