Page 120 - Aluminum_Machining_catalog_2023

P. 120

½

INDEXABLE DRILLING INSERT

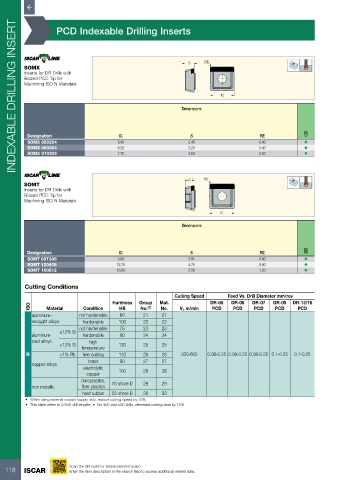

PCD Indexable Drilling Inserts

S RE

SOMX

Inserts for DR Drills with

Brazed PCD Tip for

Machining ISO N Materials

IC

Dimensions

Designation IC S RE ID5

SOMX 050204 5.40 2.40 0.40 •

SOMX 060304 6.20 3.20 0.40 •

SOMX 070305 7.70 3.60 0.50 •

S RE

SOMT

Inserts for DR Drills with

Brazed PCD Tip for

Machining ISO N Materials

IC

Dimensions

Designation IC S RE ID5

SOMT 09T306 9.00 3.81 0.60 •

SOMT 120408 12.70 4.76 0.80 •

SOMT 160512 16.00 5.56 1.20 •

Cutting Conditions

Cutting Speed Feed Vs. Drill Diameter mm/rev

Hardness Group Mat. DR-05 DR-06 DR-07 DR-09 DR-12/16

ISO Material Condition HB No. (1) No. Vc m/min PCD PCD PCD PCD PCD

aluminum- not hardenable 60 21 21

wrought alloys hardenable 100 22 22

not hardenable 75 23 23

≤12% Si

aluminum- hardenable 90 24 24

cast alloys high

>12% Si 130 25 25

temperature

N >1% Pb free cutting 110 26 26 300-600 0.08-0.25 0.08-0.25 0.08-0.25 0.1-0.25 0.1-0.25

brass 90 27 27

copper alloys

electrolytic 100 28 28

copper

duroplastics, 70 shore D 29 29

non metallic fiber plastics

hard rubber 55 shore D 30 30

• When using external coolant supply only, reduce cutting speed by 10%

• This table refers to 2/3xD drill lengths • For 4xD and 5XD drills, decrease cutting data by 15%

118 ISCAR Scan the QR code for additional information.

Enter the item description in the search field to access additional related data.