Page 116 - Aluminum_Machining_catalog_2023

P. 116

USER GUIDE

INDEXABLE DRILLING INSERT

Setup of Non-Rotating Drills

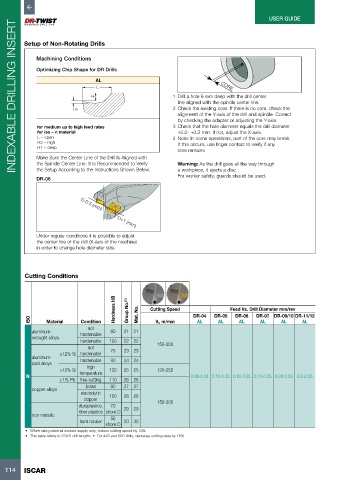

Machining Conditions

Optimizing Chip Shape for DR Drills

AL

L CORE

H2 1 Drill a hole 6 mm deep with the drill center

line aligned with the spindle center line.

2 Check the existing core. If there is no core, check the

H1

alignment of the Y-axis of the drill and spindle. Correct

by checking the adapter or adjusting the Y-axis.

for medium up to high feed rates 3 Check that the hole diameter equals the drill diameter

for iso – n material +0.0- +0.2 mm. If not, adjust the X-axis.

L – open 4 Note: In some operations, part of the core may break.

H2 – high If this occurs, use finger contact to verify if any

H1 – deep

core remains

Make Sure the Center Line of the Drill Is Aligned with

the Spindle Center Line. It Is Recommended to Verify Warning: As the drill goes all the way through

the Setup According to the Instructions Shown Below. a workpiece, it ejects a disc.

For worker safety, guards should be used.

DR-06 D-0.3 (mm)

D+1 (mm)

Under regular conditions it is possible to adjust

the center line of the drill (X-axis of the machine)

in order to change hole diameter size.

Cutting Conditions

Hardness HB Group No. (1) Cutting Speed Feed Vs. Drill Diameter mm/rev

ISO Material Condition Mat. No. Vc m/min DR-04 DR-05 DR-06 DR-07 DR-09/10 DR-11/12

AL

AL

AL

AL

AL

AL

not

aluminum- hardenable 60 21 21

wrought alloys

hardenable 100 22 22 150-300

not

≤12% Si hardenable 75 23 23

aluminum-

cast alloys hardenable 90 24 24

high

>12% Si 130 25 25 120-250

N temperature 0.08-0.24 0.12-0.25 0.12-0.25 0.12-0.25 0.20-0.30 0.2-0.35

>1% Pb free cutting 110 26 26

brass 90 27 27

copper alloys

electrolytic 100 28 28

copper

duroplastics, 70 29 29 150-300

fiber plastics shore D

non metallic 55

hard rubber 30 30

shore D

• When using external coolant supply only, reduce cutting speed by 10%

• This table refers to 2/3xD drill lengths • For 4xD and 5XD drills, decrease cutting data by 15%

114 ISCAR