Page 135 - Aluminum_Machining_catalog_2023

P. 135

USER GUIDE

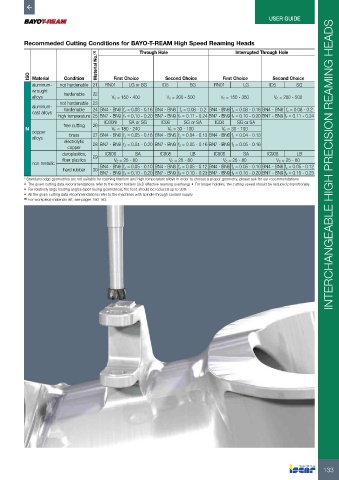

Recommeded Cutting Conditions for BAYO-T-REAM High Speed Reaming Heads

Through Hole

Interrupted Through Hole

Material No. (1)

ISO Material Condition First Choice Second Choice First Choice Second Choice

aluminum- not hardenable 21 RN01 LG or SG ID5 SG RN01 LG ID5 SG

wrought

alloys hardenable 22 Vc = 150 - 400 Vc = 200 - 500 Vc = 150 - 350 Vc = 200 - 500

not hardenable 23

aluminum- hardenable 24 BN4 - BN6 fz = 0.08 - 0.16 BN4 - BN6 fz = 0.08 - 0.2 BN4 - BN6 fz = 0.08 - 0.16 BN4 - BN6 fz = 0.08 - 0.2

cast alloys

high temperature 25 BN7 - BN9 fz = 0.10 - 0.20 BN7 - BN9 fz = 0.11 - 0.24 BN7 - BN9 fz = 0.10 - 0.20 BN7 - BN9 fz = 0.11 - 0.24

IC30N SA or SG IC08 SG or SA IC08 SG or SA

free cutting 26

N Vc = 180 - 240 Vc = 30 - 100 Vc = 30 - 100

copper brass 27 BN4 - BN6 fz = 0.05 - 0.16 BN4 - BN6 fz = 0.04 - 0.13 BN4 - BN6 fz = 0.04 - 0.13

alloys

electrolytic 28 BN7 - BN9 fz = 0.04 - 0.20 BN7 - BN9 fz = 0.05 - 0.16 BN7 - BN9 fz = 0.05 - 0.16

copper

duroplastics, 29 IC908 SA IC908 LB IC908 SA IC908 LB

fiber plastics Vc = 25 - 80 Vc = 25 - 80 Vc = 25 - 80 Vc = 25 - 80

non metallic INTERCHANGEABLE HIGH PRECISION REAMING HEADS

hard rubber 30 BN4 - BN6 fz = 0.05 - 0.10 BN4 - BN6 fz = 0.05 - 0.12 BN4 - BN6 fz = 0.05 - 0.10 BN4 - BN6 fz = 0.05 - 0.12

BN7 - BN9 fz = 0.10 - 0.20 BN7 - BN9 fz = 0.10 - 0.23 BN7 - BN9 fz = 0.10 - 0.20 BN7 - BN9 fz = 0.10 - 0.23

* Standard edge geometries are not suitable for reaming titanium and high temperature alloys In order to choose a proper geometry, please ask for our recommendations

• The given cutting data recommendations refer to the short holders (3xD effective reaming overhang) • For longer holders, the cutting speed should be reduced proportionally

• For relatively large leading angles (spot-facing geometries), the feed should be reduced up to 30%

• All the given cutting data recommendations refer to the machines with spindle through coolant supply

(1) For workpiece materials list, see pages 160-163

133