Page 139 - Aluminum_Machining_catalog_2023

P. 139

USER GUIDE

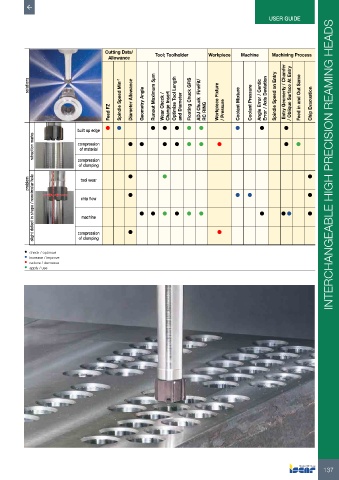

Cutting Data/ Tool; Toolholder Workpiece Machine Machining Process

Allowance

solutions Runout Maximum 5µm Optimize Tool Length Error / Axis Deviation Spindle Speed on Entry Entry Geomerty / Chamfer / Oblique Surface At Entry Feed in and Out Same

Feed FZ Spindle Speed Min -1 Diameter Allowance Geometry Angle Wear Check / Change Insert and Diameter Floating Chuck GFIS ADJ Chuck FineFit/ RC RING Workpiece Fixture / Pressure Coolant Mixture Coolant Pressure Angle Error / Centic Chip Evacuation

built up edge • • • • • • • • • •

retraction marks compression • • • • • • • • •

of material

compression

of clamping INTERCHANGEABLE HIGH PRECISION REAMING HEADS

slight defect in shape / noncircular hole chip flow • • • • • • • •• •

problem tool wear • • • • •

•

•

machine

of clamping

• check / optimize compression • •

• increase / improve

• reduce / decrease

• apply / use

137