Page 140 - Aluminum_Machining_catalog_2023

P. 140

½

INTERCHANGEABLE HIGH PRECISION REAMING HEADS

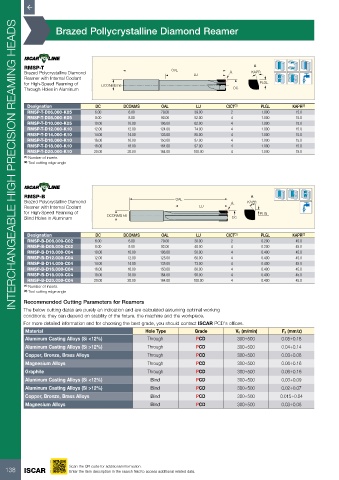

Brazed Pollycrystalline Diamond Reamer

RMSP-T OAL A

Brazed Polycrystalline Diamond LU A KAPR

Reamer with Internal Coolant

for High-Speed Reaming of DCONMS h6 PLGL

Through Holes in Aluminum DC

Designation DC DCONMS OAL LU CICT (1) PLGL KAPR (2)

RMSP-T-D06.000-K05 6.00 6.00 79.00 39.00 2 1.000 15.0

RMSP-T-D08.000-K05 8.00 8.00 92.00 52.00 4 1.000 15.0

RMSP-T-D10.000-K05 10.00 10.00 106.00 62.00 4 1.000 15.0

RMSP-T-D12.000-K10 12.00 12.00 124.00 74.00 4 1.000 15.0

RMSP-T-D14.000-K10 14.00 14.00 135.00 85.00 4 1.000 15.0

RMSP-T-D16.000-K10 16.00 16.00 150.00 97.00 4 1.000 15.0

RMSP-T-D18.000-K10 18.00 18.00 164.00 97.00 4 1.000 15.0

RMSP-T-D20.000-K10 20.00 20.00 164.00 100.00 4 1.000 15.0

(1) Number of inserts

(2) Tool cutting edge angle

RMSP-B OAL A

Brazed Polycrystalline Diamond A KAPR

Reamer with Internal Coolant LU

for High-Speed Reaming of PLGL

Blind Holes in Aluminum DCONMS h6 DC

Designation DC DCONMS OAL LU CICT (1) PLGL KAPR (2)

RMSP-B-D06.000-C02 6.00 6.00 79.00 30.00 2 0.200 45.0

RMSP-B-D08.000-C02 8.00 8.00 92.00 40.00 4 0.200 45.0

RMSP-B-D10.000-C04 10.00 10.00 106.00 50.00 4 0.400 45.0

RMSP-B-D12.000-C04 12.00 12.00 125.00 60.00 4 0.400 45.0

RMSP-B-D14.000-C04 14.00 14.00 135.00 73.00 4 0.400 45.0

RMSP-B-D16.000-C04 16.00 16.00 150.00 80.00 4 0.400 45.0

RMSP-B-D18.000-C04 18.00 18.00 164.00 90.00 4 0.400 45.0

RMSP-B-D20.000-C04 20.00 20.00 164.00 100.00 4 0.400 45.0

(1) Number of inserts

(2) Tool cutting edge angle

Recommended Cutting Parameters for Reamers

The below cutting datas are purely an indication and are calculated assuming optimal working

conditions; they can depend on stability of the fixture, the machine and the workpiece.

For more detailed information and for choosing the best grade, you should contact ISCAR PCD’s offices.

Material Hole Type Grade Vc (m/min) Fz (mm/z)

Aluminum Casting Alloys (Si <12%) Through PCD 300÷500 0.05÷0.18

Aluminum Casting Alloys (Si >12%) Through PCD 300÷500 0.04÷0.14

Copper, Bronze, Brass Alloys Through PCD 300÷500 0.03÷0.08

Magnesium Alloys Through PCD 300÷500 0.06÷0.16

Graphite Through PCD 300÷500 0.06÷0.16

Aluminum Casting Alloys (Si <12%) Blind PCD 300÷500 0.03÷0.09

Aluminum Casting Alloys (Si >12%) Blind PCD 300÷500 0.02÷0.07

Copper, Bronze, Brass Alloys Blind PCD 300÷500 0.015÷0.04

Magnesium Alloys Blind PCD 300÷500 0.03÷0.08

138 ISCAR Scan the QR code for additional information.

Enter the item description in the search field to access additional related data.