Page 138 - Aluminum_Machining_catalog_2023

P. 138

USER GUIDE

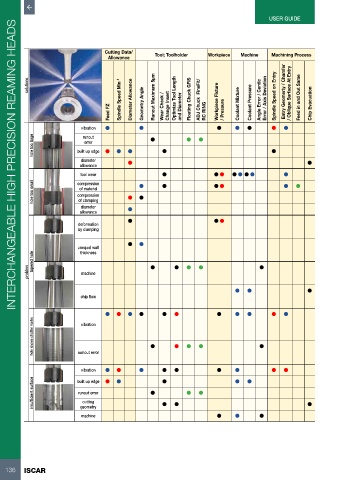

INTERCHANGEABLE HIGH PRECISION REAMING HEADS

Cutting Data/ Tool; Toolholder Workpiece Machine Machining Process

Allowance

solutions Runout Maximum 5µm Optimize Tool Length Error / Axis Deviation Spindle Speed on Entry Entry Geomerty / Chamfer / Oblique Surface At Entry Feed in and Out Same

Feed FZ Spindle Speed Min -1 Diameter Allowance Geometry Angle Wear Check / Change Insert and Diameter Floating Chuck GFIS ADJ Chuck FineFit/ RC RING Workpiece Fixture / Pressure Coolant Mixture Coolant Pressure Angle Error / Centic Chip Evacuation

• • • • • • •

vibration

runout

hole too large built up edge • • • • • • • •

error

diameter • •

allowance

• •• •••• •

tool wear

•

hole too small compression • • • •• • •

of material

compression

of clamping

diameter •

allowance

• ••

deformation

by clamping

• •

unequal wall

thickness

tapered hole • • • • •

problem machine

• • •

chip flow

• • • • • • • • • • •

hole shows chatter marks rumout error • • • • •

vibration

• • • • • • • • •

vibration • • • • •

insufficient surface runout error • • • • • •

built up edge

cutting

geometry

• • •

machine

136 ISCAR