Page 44 - Aluminum_Machining_catalog_2023

P. 44

±0.025

TOOLS AND INSERTS FOR MACHINING ALUMINUM WHEELS

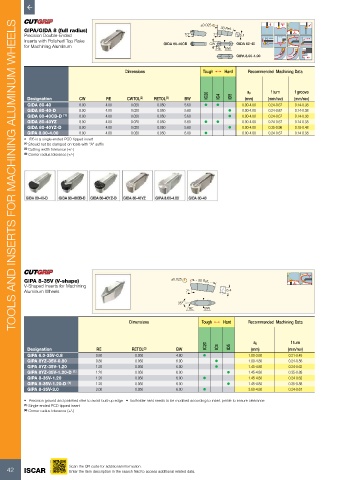

GIPA/GIDA 8 (full radius) 30 Ref.

Precision Double-Ended 10° 7° 6.4

Inserts with Polished Top Rake

for Machining Aluminum GIDA 80-40CB CW RE BW GIDA 80-40

GIPA 8.00-4.00

Dimensions Tough 1 Hard Recommended Machining Data

IC20 IC4 ID5 ap f turn f groove

Designation CW RE CWTOL (2) RETOL (3) BW (mm) (mm/rev) (mm/rev)

GIDA 80-40 8.00 4.00 0.020 0.050 5.60 • • 0.00-4.00 0.24-0.67 0.14-0.38

GIDA 80-40-D 8.00 4.00 0.020 0.050 5.60 • 0.00-4.00 0.24-0.67 0.14-0.38

GIDA 80-40CB-D (1) 8.00 4.00 0.020 0.050 5.60 • 0.00-4.00 0.24-0.67 0.14-0.38

GIDA 80-40YZ 8.00 4.00 0.020 0.050 5.60 • • 0.00-4.00 0.24-0.67 0.14-0.38

GIDA 80-40YZ-D 8.00 4.00 0.020 0.050 5.60 • 0.00-4.00 0.35-0.96 0.18-0.48

GIPA 8.00-4.00 8.00 4.00 0.020 0.050 6.00 • 0.00-4.00 0.24-0.67 0.14-0.38

• ID5 is a single-ended PCD tipped insert

(1) Should not be clamped on tools with "A" suffix

(2) Cutting width tolerance (+/-)

(3) Corner radius tolerance (+/-)

GIPA 8-35V (V-shape) ±0.025 30 Ref.

V-Shaped Inserts for Machining

Aluminum Wheels 7° 6.4

35°

RE BW

Dimensions Tough 1 Hard Recommended Machining Data

f turn

ap

Designation RE RETOL (2) BW IC20 IC4 ID5 (mm) (mm/rev)

GIPA 6.0-35V-0.8 0.80 0.050 4.80 • 1.00-3.60 0.21-0.48

GIPA 8YZ-35V-0.80 0.80 0.050 6.00 • 1.00-4.80 0.24-0.56

GIPA 8YZ-35V-1.20 1.20 0.050 6.00 • 1.45-4.80 0.24-0.62

GIPA 8YZ-35V-1.20-D (1) 1.20 0.050 6.00 • 1.45-4.80 0.35-0.88

GIPA 8-35V-1.20 1.20 0.050 6.00 • 1.45-4.80 0.24-0.62

GIPA 8-35V-1.20-D (1) 1.20 0.050 6.00 • 1.45-4.80 0.35-0.88

GIPA 8-35V-3.0 3.00 0.050 6.00 • 3.60-4.80 0.24-0.67

• Precision ground and polished rake to avoid built-up edge • Toolholder seat needs to be modified according to insert profile to ensure clearance

(1) Single-ended PCD tipped insert

(2) Corner radius tolerance (+/-)

42 ISCAR Scan the QR code for additional information.

Enter the item description in the search field to access additional related data.