Page 45 - Aluminum_Machining_catalog_2023

P. 45

±0.1

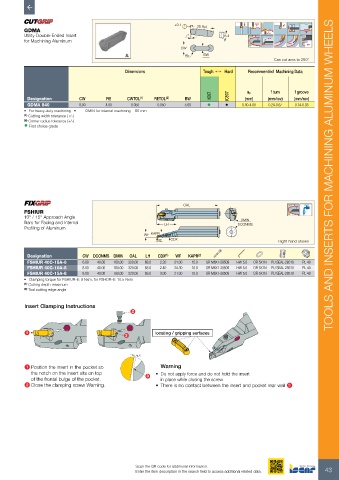

GDMA 30 Ref.

Utility Double-Ended Insert 7° 6.4

for Machining Aluminum

CW

RE BW

Can cut arcs to 250°

Dimensions Tough 1 Hard Recommended Machining Data

IC07 IC507 ap f turn f groove

Designation CW RE CWTOL (1) RETOL (2) BW (mm) (mm/rev) (mm/rev)

GDMA 840 8.00 4.00 0.050 0.050 5.60 • • 0.00-4.00 0.24-0.67 0.14-0.38

• For heavy-duty machining • DMIN for internal machining = 65 mm

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

• First choice grade

OAL TOOLS AND INSERTS FOR MACHINING ALUMINUM WHEELS

FSHIUR

10° / 15° Approach Angle

DMIN

Bars for Facing and Internal LH DCONMS

Profiling of Aluminum

WF KAPR

RE CDX Right-hand shown

Designation CW DCONMS DMIN OAL LH CDX (1) WF KAPR (2)

FSHIUR 40C-15A-6 6.00 40.00 160.00 320.00 68.0 2.20 21.00 15.0 SR M6X1-28509 HW 5.0 OR 5X1N PU SEAL-28510 PL 40

FSHIUR 40C-10A-8 8.00 40.00 160.00 320.00 68.0 2.40 24.30 10.0 SR M6X1-28509 HW 5.0 OR 5X1N PU SEAL-28510 PL 40

FSHIUR 40C-15A-8 8.00 40.00 160.00 320.00 68.0 3.00 21.00 15.0 SR M6X1-28509 HW 5.0 OR 5X1N PU SEAL-28510 PL 40

• Clamping torque for FSHIUR-6: 9 Nxm, for FSHDR-8: 10.5 Nxm

(1) Cutting depth maximum

(2) Tool cutting edge angle

Insert Clamping Instructions

2

1 locating / gripping surfaces

3

1 Position the insert in the pocket so Warning

the notch on the insert sits on top • Do not apply force and do not hold the insert

of the frontal bulge of the pocket. 3 in place while closing the screw

2 Close the clamping screw Warning. • There is no contact between the insert and pocket rear wall 3 .

Scan the QR code for additional information.

Enter the item description in the search field to access additional related data. 43