Page 66 - ISCAR FACE GROOVING LINES

P. 66

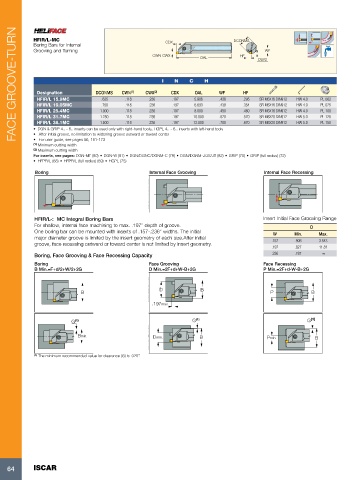

FACE GROOVE-TURN HFIR/L-MC CDX DCONMS

Boring Bars for Internal CWN-CWX

Grooving and Turning WF

OAL HF

CW/2

INCH

Designation DCONMS CWN(1) CWX(2) CDX OAL WF HF

HFIR/L 15.9MC .625 .118 .236 .197 5.906 .438 .295 SR M5X16 DIN912 HW 4.0 PL 062

HFIR/L 19.05MC .750 .118 .236 .197 6.693 .438 .354 SR M5X16 DIN912 HW 4.0 PL 075

1.000 .118 .236 .197 8.000 .450 .460 SR M5X16 DIN912 HW 4.0 PL 100

HFIR/L 25.4MC HW 5.0 PL 125

HW 5.0 PL 150

HFIR/L 31.7MC 1.250 .118 .236 .197 10.000 .570 .570 SR M6X20 DIN912

HFIR/L 38.1MC

1.500 .118 .236 .197 12.000 .700 .670 SR M6X20 DIN912

• DGN & GRIP 4.. - 6.. inserts can be used only with right-hand tools, HGPL 4.. - 6.. inserts with left-hand tools

• After initial groove, no limitation to widening groove outward or toward center

• For user guide, see pages 56, 161-173

(1) Minimum cutting width

(2) Maximum cutting width

For inserts, see pages: DGN-MF (80) • DGN-W (81) • DGN/DGNC/DGNM-C (79) • DGN/DGNM-J/JS/JT (82) • GRIP (70) • GRIP (full radius) (72)

• HFPR/L (68) • HFPR/L (full radius) (69) • HGPL (75)

Boring Internal Face Grooving Internal Face Recessing

HFIR/L-: MC Integral Boring Bars Insert Initial Face Grooving Range

For shallow, internal face machining to max. .197” depth of groove.

One boring bar can be mounted with inserts of .157-.236” widths. The initial D

major diameter groove is limited by the insert geometry of each size.After initial

groove, face recessing outward or toward center is not limited by insert geometry. W Min. Max.

.157 .906 3.543

.197 .827 11.81

Boring, Face Grooving & Face Recessing Capacity .236 .787 ∞

Boring Face Grooving Face Recessing

B Min.=F+d/2+W/2+2G D Min.=2F+d+W-B+2G P Min.=2F+d-W-B+2G

B D B PB

.197max

G(1) G(1) Pmin. G(1)

Bmin. Dmin. B B

(1) The minimum recommended value for clearance (G) is .020”.

64 ISCAR