Page 128 - HOLE MAKING CATALOG p001-148

P. 128

INDEXABLE DRILLS USER GUIDE

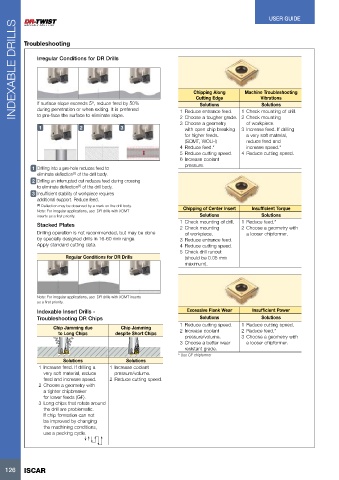

Troubleshooting

Irregular Conditions for DR Drills

If surface slope exceeds 5º, reduce feed by 50% Chipping Along Machine Troubleshooting

during penetration or when exiting. It is preferred Cutting Edge Vibrations

to pre-face the surface to eliminate slope.

Solutions Solutions

123

1 Reduce entrance feed. 1 Check mounting of drill.

1 Drilling into a pre-hole reduces feed to 2 Choose a tougher grade. 2 Check mounting

eliminate deflection(1) of the drill body. 3 Choose a geometry

of workpiece.

2 Drilling an interrupted cut reduces feed during crossing with open chip breaking 3 Increase feed. If drilling

to eliminate deflection(1) of the drill body. for higher feeds.

(SOMT, WOLH) a very soft material,

3 Insufficient stability of workpiece requires 4 Reduce feed.* reduce feed and

additional support. Reduce feed. 5 Reduce cutting speed. increase speed.*

6 Increase coolant 4 Reduce cutting speed.

(1) Deflection may be observed by a mark on the drill body. pressure.

Note: For irregular applications, use DR drills with XOMT

inserts as a first priority. Chipping of Center Insert Insufficient Torque

Stacked Plates Solutions Solutions

Drilling operation is not recommended, but may be done

by specially designed drills in 16-60 mm range. 1 Check mounting of drill. 1 Reduce feed.*

Apply standard cutting data. 2 Check mounting 2 Choose a geometry with

Regular Conditions for DR Drills of workpiece. a looser chipformer.

3 Reduce entrance feed.

4 Reduce cutting speed.

5 Check drill runout

(should be 0.05 mm

maximum).

Note: For irregular applications, use DR drills with XOMT inserts

as a first priority.

Indexable Insert Drills - Excessive Flank Wear Insufficient Power

Troubleshooting DR Chips

Solutions Solutions

Chip Jamming due Chip Jamming

to Long Chips despite Short Chips 1 Reduce cutting speed. 1 Reduce cutting speed.

2 Increase coolant 2 Reduce feed.*

3 Choose a geometry with

pressure/volume.

3 Choose a better wear a looser chipformer.

resistant grade.

* Use GF chipformer

Solutions Solutions

1 Increase feed. If drilling a 1 Increase coolant

very soft material, reduce pressure/volume.

feed and increase speed. 2 Reduce cutting speed.

2 Choose a geometry with

a tighter chipbreaker

for lower feeds (GF).

3 Long chips that rotate around

the drill are problematic.

If chip formation can not

be improved by changing

the machining conditions,

use a pecking cycle.

126 ISCAR