Page 77 - HOLE MAKING CATALOG p001-148

P. 77

USER GUIDE

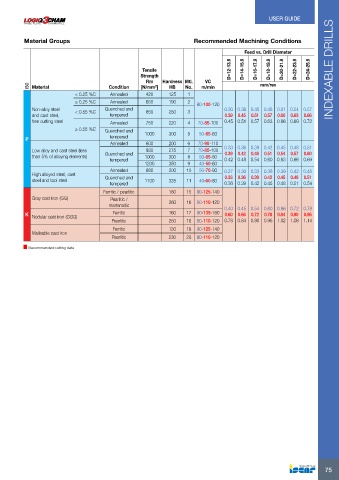

ISO

D=12-13.9Material Groups

D=14-15.9

D=16-17.9

D=18-19.9

D=20-21.9

D=22-23.9

D=24-25.9

INDEXABLE DRILLS

Recommended Machining Conditions

Feed vs. Drill Diameter

Material Condition Tensile Hardness Mtl. VC mm/rev

Annealed Strength HB No. m/min

Non-alloy steel Annealed

and cast steel, Quenched and Rm

free cutting steel tempered [N/mm2]

P < 0.25 %C Annealed 420 125 1

≥ 0.25 %C

< 0.55 %C Quenched and 650 190 2 80-100-120 0.30 0.36 0.45 0.48 0.51 0.54 0.57

tempered 0.39 0.45 0.51 0.57 0.60 0.63 0.66

≥ 0.55 %C Annealed 850 250 3

Quenched and 750 220 4 70-85-100 0.45 0.51 0.57 0.63 0.66 0.69 0.72

tempered

1000 300 5 50-65-80

Annealed

Low alloy and cast steel (less Quenched and 600 200 6 70-90-110 0.33 0.36 0.39 0.42 0.45 0.48 0.51

than 5% of alloying elements) 930 275 7 70-85-100

tempered 1000 300 8 50-65-80 0.39 0.42 0.48 0.51 0.54 0.57 0.60

1200 350 9 40-50-60 0.42 0.48 0.54 0.60 0.63 0.66 0.69

Ferritic / pearlitic 680

High alloyed steel, cast Pearlitic / 200 10 50-70-90 0.27 0.30 0.33 0.36 0.39 0.42 0.45

steel and tool steel martensitic 1100

Ferritic 325 11 40-60-80 0.33 0.36 0.39 0.42 0.45 0.48 0.51

0.36 0.39 0.42 0.45 0.48 0.51 0.54

Pearlitic

180 15 90-125-140

Ferritic

Gray cast iron (GG) 260 16 80-110-120

K Nodular cast iron (GGG) Pearlitic

160 17 90-135-160 0.40 0.45 0.54 0.60 0.66 0.72 0.78

Malleable cast iron 0.60 0.66 0.72 0.78 0.84 0.90 0.96

Recommended cutting data 250 18 80-110-120 0.78 0.84 0.90 0.96 1.02 1.08 1.14

130 19 90-125-140

230 20 80-110-120

75