Page 49 - TURNING CATALOG p255-458

P. 49

LH GROOVE-TURN

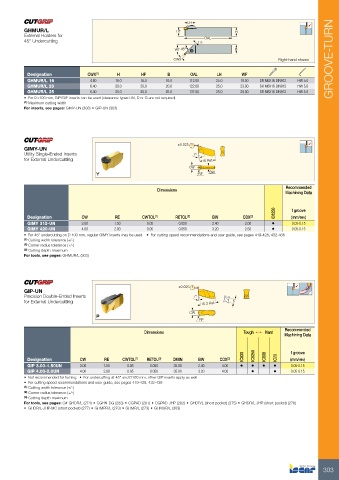

GHMUR/L HF H

External Holders for WF 45°

45° Undercutting OAL

1.5

CWX B

Right-hand shown

Designation CWX(1) H HF B OAL LH WF

112.00 25.0 19.00

GHMUR/L 16 4.80 16.0 16.0 16.0 122.00 25.0 23.00 SR M6X16 DIN912 HW 5.0

GHMUR/L 20 6.40 20.0 20.0 20.0 137.00 25.0 28.00 SR M6X16 DIN912 HW 5.0

6.40 25.0 25.0 25.0 SR M6X16 DIN912 HW 5.0

GHMUR/L 25

• For D>100 mm, GIP/GIF inserts can be used (clearance types UN, D or G are not required).

(1) Maximum cutting width

For inserts, see pages: GIMY-UN (303) • GIP-UN (303)

GIMY-UN ±0.025

Utility Single-Ended Inserts

for External Undercutting 7°

15 Ref.

CW BW

RE

Dimensions Recommended

Machining Data

Designation CW RE CWTOL(1) RETOL(2) BW CDX(3) IC8250 f groove

GIMY 315-UN 3.00 1.50 0.05 0.050 2.40 2.00 • (mm/rev)

GIMY 420-UN 4.00 2.00 0.05 0.050 3.20 2.50 • 0.05-0.15

0.05-0.15

• For 45° undercutting on D 100 mm, regular GIMY inserts may be used. • For cutting speed recommendations and user guide, see pages 419-428, 432-436

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Cutting depth maximum

For tools, see pages: GHMUR/L (303)

GIP-UN ±0.025 5

Precision Double-Ended Inserts

for External Undercutting 7°

15.3 Ref.

CW

RE

Dimensions Tough 1 Hard Recommended

Machining Data

IC830 f groove

IC8250

Designation CW RE CWTOL(1) RETOL(2) DMIN BW CDX(3) IC808 (mm/rev)

IC20

GIP 3.00-1.50UN 3.00 1.50 0.05 0.050 35.00 2.40 4.00 • • • • 0.05-0.15

• • 0.05-0.15

GIP 4.00-2.0UN 4.00 2.00 0.05 0.050 35.00 3.20 4.00

• Not recommended for turning. • For undercutting at 45° and D100 mm, other GIP inserts apply as well

• For cutting speed recommendations and user guide, see pages 419-428, 432-436

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Cutting depth maximum

For tools, see pages: C#-GHDR/L (274) • CGHN-DG (283) • CGPAD (281) • CGPAD-JHP (282) • GHDR/L (short pocket) (275) • GHDR/L-JHP (short pocket) (276)

• GHDR/L-JHP-MC (short pocket) (277) • GHMPR/L (273) • GHMR/L (273) • GHMUR/L (303)

303