Page 91 - HOLE_MAKING_CATALOG_INCH_2022_P447-P626

P. 91

60° 91 º

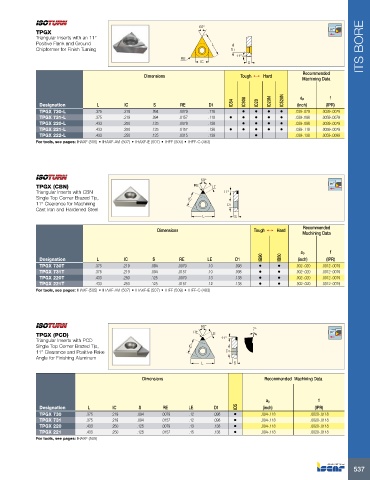

TPGX

Triangular Inserts with an 11°

Positive Flank and Ground L

Chipformer for Finish Turning D1 ITS BORE

11°

RE

IC S

Dimensions Tough 1 Hard Recommended

Machining Data

f

ap

Designation L IC S RE D1 IC54 IC908 IC20 IC20N IC520N (inch) (IPR)

TPGX 730-L .375 .219 .094 .0079 .118 • • • • .039-.079 .0039-.0079

TPGX 731-L .375 .219 .094 .0157 .118 • • • • • .039-.098 .0059-.0079

TPGX 220-L .433 .250 .125 .0079 .138 • • • • .039-.098 .0039-.0079

TPGX 221-L .433 .250 .125 .0157 .138 • • • • • .039-.118 .0059-.0079

TPGX 222-L .433 .250 .125 .0315 .138 • .039-.138 .0059-.0098

For tools, see pages: IHAXF (505) • IHAXF-AVI (507) • IHAXF-E (507) • IHFF (509) • IHFF-C (483)

60°

TPGX (CBN) RE LE 91 º

Triangular Inserts with CBN 11°

Single Top Corner Brazed Tip, IC

11° Clearance for Machining D1

Cast Iron and Hardened Steel

L S

Recommended

Dimensions Tough 1 Hard

Machining Data

ap f

Designation L IC S RE LE D1 IB90 IB50 (inch) (IPR)

TPGX 730T .375 .219 .094 .0079 .10 .098 • • .002-.020 .0012-.0079

TPGX 731T .375 .219 .094 .0157 .10 .098 • • .002-.020 .0012-.0079

TPGX 220T .433 .250 .125 .0079 .13 .138 • • .002-.020 .0012-.0079

TPGX 221T .433 .250 .125 .0157 .12 .138 • • .002-.020 .0012-.0079

For tools, see pages: IHAXF (505) • IHAXF-AVI (507) • IHAXF-E (507) • IHFF (509) • IHFF-C (483)

60° 7°

TPGX (PCD) RE LE 11° 91 º

Triangular Inserts with PCD

Single Top Corner Brazed Tip, IC

11° Clearance and Positive Rake D1

Angle for Finishing Aluminum

L S

Dimensions Recommended Machining Data

ap f

Designation L IC S RE LE D1 ID5 (inch) (IPR)

TPGX 730 .375 .219 .094 .0079 .12 .098 • .004-.118 .0020-.0118

TPGX 731 .375 .219 .094 .0157 .12 .098 • .004-.118 .0020-.0118

TPGX 220 .433 .250 .125 .0079 .13 .138 • .004-.118 .0020-.0118

TPGX 221 .433 .250 .125 .0157 .15 .138 • .004-.118 .0020-.0118

For tools, see pages: IHAXF (505)

537