Page 53 - MILLING_CATALOG_INCH_2022_P1-P92

P. 53

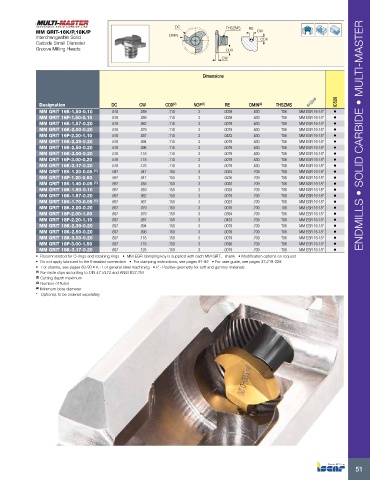

MM GRIT-16K/P,18K/P DC THSZMS RE CW

Interchangeable Solid DMIN CDX

Carbide Small Diameter

Groove Milling Heads CDX

CW

Dimensions

IC528

Designation DC CW CDX (2) NOF (3) RE DMIN (4) THSZMS

MM GRIT 16K-1.50-0.10 .618 .059 .110 3 .0039 .630 T06 MM EGR 16-18* •

MM GRIT 16P-1.50-0.10 .618 .059 .110 3 .0039 .630 T06 MM EGR 16-18* •

MM GRIT 16K-1.57-0.20 .618 .062 .110 3 .0079 .630 T06 MM EGR 16-18* •

MM GRIT 16K-2.00-0.20 .618 .079 .110 3 .0079 .630 T06 MM EGR 16-18* •

MM GRIT 16P-2.20-1.10 .618 .087 .110 3 .0433 .630 T06 MM EGR 16-18* • ENDMILLS • SOLID CARBIDE • MULTI-MASTER

MM GRIT 16K-2.39-0.20 .618 .094 .110 3 .0079 .630 T06 MM EGR 16-18* •

MM GRIT 16K-2.50-0.20 .618 .098 .110 3 .0079 .630 T06 MM EGR 16-18* •

MM GRIT 16K-3.00-0.20 .618 .118 .110 3 .0079 .630 T06 MM EGR 16-18* •

MM GRIT 16P-3.00-0.20 .618 .118 .110 3 .0079 .630 T06 MM EGR 16-18* •

MM GRIT 16K-3.17-0.20 .618 .125 .110 3 .0079 .630 T06 MM EGR 16-18* •

MM GRIT 18K-1.20-0.05 (1) .697 .047 .150 3 .0020 .709 T06 MM EGR 16-18* •

MM GRIT 18P-1.20-0.60 .697 .047 .150 3 .0236 .709 T06 MM EGR 16-18* •

MM GRIT 18K-1.40-0.05 (1) .697 .055 .150 3 .0020 .709 T06 MM EGR 16-18* •

MM GRIT 18K-1.50-0.10 .697 .059 .150 3 .0039 .709 T06 MM EGR 16-18* •

MM GRIT 18K-1.57-0.20 .697 .062 .150 3 .0079 .709 T06 MM EGR 16-18* •

MM GRIT 18K-1.70-0.05 (1) .697 .067 .150 3 .0020 .709 T06 MM EGR 16-18* •

MM GRIT 18K-2.00-0.20 .697 .079 .150 3 .0079 .709 T06 MM EGR 16-18* •

MM GRIT 18P-2.00-1.00 .697 .079 .150 3 .0394 .709 T06 MM EGR 16-18* •

MM GRIT 18P-2.20-1.10 .697 .087 .150 3 .0433 .709 T06 MM EGR 16-18* •

MM GRIT 18K-2.39-0.20 .697 .094 .150 3 .0079 .709 T06 MM EGR 16-18* •

MM GRIT 18K-2.50-0.20 .697 .098 .150 3 .0079 .709 T06 MM EGR 16-18* •

MM GRIT 18K-3.00-0.20 .697 .118 .150 3 .0079 .709 T06 MM EGR 16-18* •

MM GRIT 18P-3.00-1.50 .697 .118 .150 3 .0590 .709 T06 MM EGR 16-18* •

MM GRIT 18K-3.17-0.20 .697 .125 .150 3 .0079 .709 T06 MM EGR 16-18* •

• Recommended for O-rings and retaining rings • MM EGR clamping key is supplied with each MM GRT... shank • Modification options on request

• Do not apply lubricant to the threaded connection • For clamping instructions, see pages 91-92 • For user guide, see pages 37,219-228

• For shanks, see pages 83-90 • K - For general steel machining • P - Positive geometry for soft and gummy materials

(1) For circle clips according to DIN 471/472 and ANSI B27.7M

(2) Cutting depth maximum

(3) Number of flutes

(4) Minimum bore diameter

* Optional, to be ordered separately

51