Page 49 - MILLING_CATALOG_INCH_2022_P1-P92

P. 49

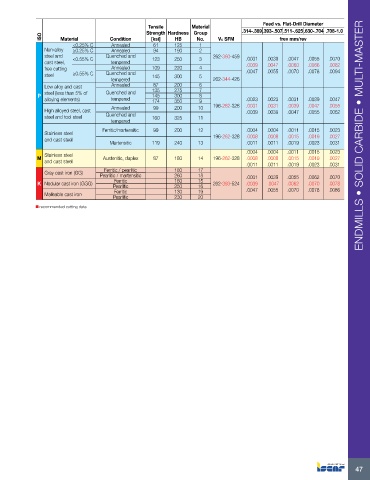

Feed vs. Flat-Drill Diameter

Tensile Material

Strength Hardness Group .314-.389.393-.507.511-.625.630-.704 .708-1.0

ISO Material Condition [ksi] HB No. Vc SFM frev mm/rev

<0.25% C Annealed 61 125 1

Non-alloy ≥0.25% C Annealed 94 190 2

steel and <0.55% C Quenched and 123 250 3 262-360-459 .0031 .0039 .0047 .0055 .0070

cast steel, tempered .0039 .0047 .0060 .0066 .0082

free cutting Annealed 109 220 4 .0047 .0055 .0070 .0078 .0094

steel ≥0.55% C Quenched and 145 300 5

tempered 262-344-426

Low alloy and cast Annealed 87 200 6

steel (less than 5% of Quenched and 135 275 7

P 145 300 8

alloying elements) tempered 174 350 9 .0023 .0023 .0031 .0039 .0047

High alloyed steel, cast Annealed 99 200 10 196-262-328 .0031 .0031 .0039 .0047 .0055

.0039

.0055

.0047

.0062

.0039

steel and tool steel Quenched and 160 325 11

tempered

Ferritic/martensitic 99 200 12 .0004 .0004 .0011 .0015 .0023

Stainless steel 196-262-328 .0008 .0008 .0015 .0019 .0027 ENDMILLS • SOLID CARBIDE • MULTI-MASTER

and cast steel

Martensitic 119 240 13 .0011 .0011 .0019 .0023 .0031

.0004 .0004 .0011 .0015 .0023

Stainless steel

M Austenitic, duplex 87 180 14 196-262-328 .0008 .0008 .0015 .0019 .0027

and cast steel

.0011 .0011 .0019 .0023 .0031

Ferritic / pearlitic 180 17

Gray cast iron (GG) Pearlitic / martensitic 260 18

Ferritic 160 15 .0031 .0039 .0055 .0062 .0070

K Nodular cast iron (GGG) Pearlitic 250 16 262-393-524 .0039 .0047 .0062 .0070 .0078

Ferritic

Malleable cast iron Pearlitic 130 19 .0047 .0055 .0070 .0078 .0086

20

230

recommended cutting data

47