Page 80 - MILLING_CATALOG_INCH_2022_P1-P92

P. 80

Rd°

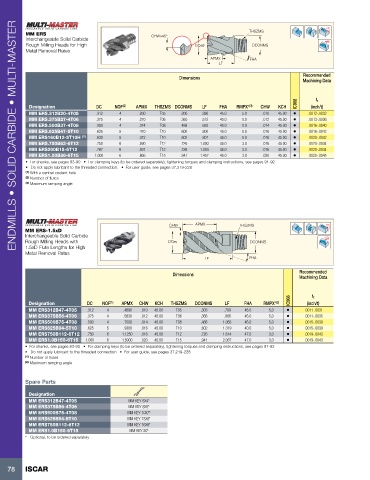

ENDMILLS • SOLID CARBIDE • MULTI-MASTER

MM ERS CHWx45° THSZMS

Interchangeable Solid Carbide

Rough Milling Heads for High DCe9 DCONMS

Metal Removal Rates

APMX FHA

LF

Recommended

Dimensions

Machining Data

IC908 fz

Designation DC NOF (2) APMX THSZMS DCONMS LF FHA RMPX° (3) CHW KCH (inch/t)

MM ERS.312B20-4T05 .312 4 .200 T05 .300 .390 45.0 5.0 .010 45.00 • .0012-.0032

MM ERS.375B27-4T06 .375 4 .270 T06 .360 .512 45.0 5.0 .012 45.00 • .0013-.0036

MM ERS.500B37-4T08 .500 4 .374 T08 .488 .650 45.0 5.0 .014 45.00 • .0016-.0040

MM ERS.625B47-5T10 .625 5 .470 T10 .600 .800 45.0 5.0 .016 45.00 • .0016-.0042

MM ERS160B12-5T10H (1) .630 5 .472 T10 .602 .807 45.0 5.0 .016 45.00 • .0020-.0042

MM ERS.750B62-6T12 .750 6 .590 T12 .726 1.000 45.0 3.0 .016 45.00 • .0020-.0044

MM ERS200B15-6T12 .787 6 .591 T12 .726 1.004 45.0 3.0 .016 45.00 • .0020-.0044

MM ERS1.00B86-6T15 1.000 6 .866 T15 .941 1.457 45.0 3.0 .020 45.00 • .0020-.0045

• For shanks, see pages 83-90 • For clamping keys (to be ordered separately), tightening torques and clamping instructions, see pages 91-92

• Do not apply lubricant to the threaded connection. • For user guide, see pages 37,219-228

(1) With a central coolant hole

(2) Number of flutes

(3) Maximum ramping angle

CHW APMX THSZMS Rd°

MM ERS-1.5xD

Interchangeable Solid Carbide

Rough Milling Heads with DCe9 DCONMS

1.5xD Flute Lengths for High

Metal Removal Rates

LF FHA

Recommended

Dimensions Machining Data

IC908 fz

Designation DC NOF (1) APMX CHW KCH THSZMS DCONMS LF FHA RMPX° (2) (inch/t)

MM ERS312B47-4T05 .312 4 .4690 .010 45.00 T05 .303 .709 46.0 5.0 • .0011-.0031

MM ERS375B56-4T06 .375 4 .5630 .012 45.00 T06 .366 .866 46.0 5.0 • .0011-.0035

MM ERS500B75-4T08 .500 4 .7500 .014 45.00 T08 .488 1.063 46.0 5.0 • .0015-.0039

MM ERS625B94-5T10 .625 5 .9380 .016 45.00 T10 .602 1.319 40.0 5.0 • .0015-.0039

MM ERS750B112-6T12 .750 6 1.1250 .016 45.00 T12 .726 1.614 47.0 3.0 • .0019-.0043

MM ERS1.0B150-6T15 1.000 6 1.5000 .020 45.00 T15 .941 2.067 47.0 3.0 • .0019-.0043

• For shanks, see pages 83-90 • For clamping keys (to be ordered separately), tightening torques and clamping instructions, see pages 91-92

• Do not apply lubricant to the threaded connection • For user guide, see pages 37,219-228

(1) Number of flutes

(2) Maximum ramping angle

Spare Parts

Designation

MM ERS312B47-4T05 MM KEY 6X4*

MM ERS375B56-4T06 MM KEY 8X5*

MM ERS500B75-4T08 MM KEY 10X7*

MM ERS625B94-5T10 MM KEY 13X8*

MM ERS750B112-6T12 MM KEY 16X9*

MM ERS1.0B150-6T15 MM KEY 20*

* Optional, to be ordered separately

78 ISCAR