Page 128 - MILLING_CATALOG_INCH_2022_P361-P592

P. 128

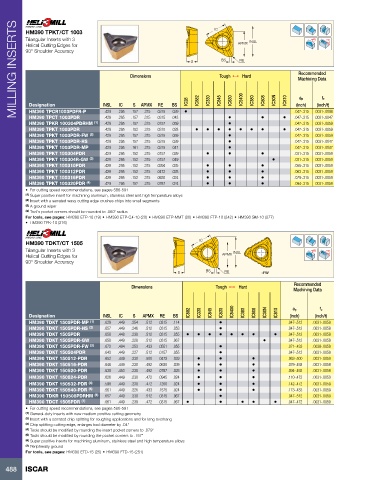

MILLING INSERTS HM390 TPKT/CT 1003 Dimensions S IC Tough 1 Hard INSL Machining Data Rd°

Triangular Inserts with 3

APMX

Helical Cutting Edges for

90° Shoulder Accuracy

BS

RE

Recommended

fz

ap

(inch/t)

(inch)

BS

RE

Designation

IC

S

.429

.315

HM390 TPCR1003PDFR-P

.0315

.315

HM390 TPCT 1003PDR

.295

.043

.047-.315

.429

.157

.0031-.0047

•

.0157

.315

.059

.047-.315

.157

.295

.429

.0031-.0059

HM390 TPKR 100304PDRHM (1) INSL .295 .157 APMX .0315 .039 • IC28 IC882 IC330 IC845 • IC830 IC5400 IC380 • IC808 IC30N • IC810 .047-.315 .0031-.0098

HM390 TPKT 1003PDR .429 .295 .152 .315 .0315 .028 • • • • • • • • .047-.315 .0031-.0059

HM390 TPKT 1003PDR-FW (2) .429 .295 .157 .315 .0315 .059 • .047-.315 .0031-.0059

HM390 TPKT 1003PDR-HS .429 .295 .157 .315 .0315 .039 • .047-.315 .0031-.0047

HM390 TPKT 1003PDR-MP .429 .295 .161 .315 .0315 .047 • .047-.315 .0031-.0047

HM390 TPKT 100304PDR .429 .295 .152 .315 .0157 .039 • • • .031-.315 .0031-.0059

HM390 TPKT 100304R-GW (3) .429 .295 .152 .315 .0157 .049 • .031-.315 .0031-.0059

HM390 TPKT 100310PDR .429 .295 .152 .315 .0394 .035 • • • .055-.315 .0031-.0059

HM390 TPKT 100312PDR .429 .295 .152 .315 .0472 .028 • • • .063-.315 .0031-.0059

HM390 TPKT 100316PDR .429 .295 .152 .315 .0630 .024 • • • .079-.315 .0031-.0059

HM390 TPKT 100320PDR (4) .429 .295 .152 .315 .0787 .024 • • • .094-.315 .0031-.0059

• For cutting speed recommendations, see pages 586-591

(1) Super positive insert for machining aluminum, stainless steel and high temperature alloys

(2) Insert with a serrated wavy cutting edge crushes chips into small segments

(3) A ground wiper

(4) Tool's pocket corners should be rounded to .060" radius

For tools, see pages: HM390 ETP-10 (19) • HM390 ETP-C#-10 (20) • HM390 ETP-MMT (20) • HM390 FTP-10 (242) • HM390 SM-10 (277)

• HM390 TPK-10 (276)

HM390 TDKT/CT 1505 IC

Triangular Inserts with 3 INSL Rd°

Helical Cutting Edges for APMX

90° Shoulder Accuracy

S BS RE -FW

Recommended

Dimensions Tough 1 Hard

Machining Data

IC882 IC330 IC845 IC830 IC5400 IC380 IC808 IC30N IC810 ap fz

Designation INSL IC S APMX RE BS (inch) (inch/t)

HM390 TDKT 1505PDR-MP (1) .629 .449 .254 .512 .0315 .114 • .047-.512 .0031-.0059

HM390 TDKT 1505PDR-HS (2) .657 .449 .246 .512 .0315 .053 • .047-.512 .0031-.0059

HM390 TDKT 1505PDR .658 .448 .230 .512 .0315 .055 • • • • • • • • .047-.512 .0031-.0059

HM390 TDKT 1505PDR-GW .650 .449 .228 .512 .0315 .067 • .047-.512 .0031-.0059

HM390 TDKT 1505PDR-FW (3) .672 .484 .253 .433 .0551 .055 • .071-.433 .0039-.0059

HM390 TDKT 150504PDR .643 .449 .227 .512 .0157 .055 • .047-.512 .0031-.0059

HM390 TDKT 150512-PDR .652 .449 .230 .500 .0472 .039 • • • .063-.500 .0031-.0059

HM390 TDKT 150516-PDR .646 .449 .230 .492 .0630 .039 • • • .079-.492 .0031-.0059

HM390 TDKT 150520-PDR .638 .453 .230 .492 .0787 .028 • • • .094-.492 .0031-.0059

HM390 TDKT 150524-PDR .626 .449 .230 .472 .0945 .024 • • • .110-.472 .0031-.0059

HM390 TDKT 150532-PDR (4) .598 .449 .230 .472 .1260 .024 • • • .142-.472 .0031-.0059

HM390 TDKT 150540-PDR (5) .561 .449 .226 .433 .1575 .024 • • • .173-.433 .0031-.0059

HM390 TDKR 150508PDRHM (6) .657 .449 .230 .512 .0315 .067 • .047-.512 .0031-.0059

HM390 TDCT 1505PDR (7) .661 .449 .239 .472 .0315 .067 • • • • • .047-.472 .0031-.0059

• For cutting speed recommendations, see pages 586-591

(1) General-duty inserts with new medium positive cutting geometry

(2) Insert with a serrated chip splitting for roughing applications and for long overhang

(3) Chip splitting cutting edge, enlarges tool diameter by .04"

(4) Tools should be modified by rounding the insert pocket corners to .079"

(5) Tools should be modified by rounding the pocket corners to .157"

(6) Super positive inserts for machining aluminum, stainless steel and high temperature alloys

(7) Peripherally ground

For tools, see pages: HM390 ETD-15 (25) • HM390 FTD-15 (251)

488 ISCAR