Page 129 - MILLING_CATALOG_INCH_2022_P361-P592

P. 129

IC

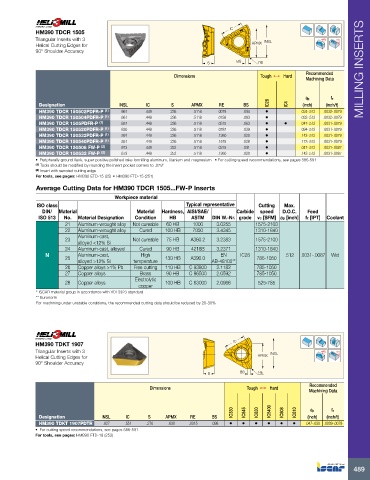

HM390 TDCR 1505

Triangular Inserts with 3 INSL Rd°

Helical Cutting Edges for APMX

90° Shoulder Accuracy

S BS RE

Dimensions Tough 1 Hard Recommended MILLING INSERTS

Machining Data

ap fz

Designation INSL IC S APMX RE BS IC28 IC4 (inch) (inch/t)

HM390 TDCR 150502PDFR-P (1) .661 .449 .236 .5118 .0079 .094 • .024-.512 .0032-.0079

HM390 TDCR 150504PDFR-P (1) .661 .449 .236 .5118 .0158 .093 • .032-.512 .0032-.0079

HM390 TDCR 1505PDFR-P (1) .657 .449 .236 .5118 .0315 .063 • • .047-.512 .0031-.0079

HM390 TDCR 150520PDFR-P (1) .630 .449 .236 .5118 .0787 .039 • .094-.512 .0031-.0079

HM390 TDCR 150532PDFR-P (1) .591 .449 .236 .5118 .1260 .020 • .142-.512 .0031-.0079

HM390 TDCR 150540PDFR-P (1) .551 .449 .236 .5118 .1575 .028 • .173-.512 .0031-.0079

HM390 TDCR 150508 FW-P (2) .673 .449 .252 .5118 .0315 .091 • .047-.512 .0031-.0087

HM390 TDCR 150532 FW-P (2) .673 .449 .252 .5118 .1260 .020 • .142-.512 .0031-.0087

• Peripherally ground flank, super positive polished rake formilling aluminum, titanium and magnesium • For cutting speed recommendations, see pages 586-591

(1) Tools should be modified by rounding the insert pocket corners to .079"

(2) Insert with serrated cutting edge

For tools, see pages: HM390 ETD-15 (25) • HM390 FTD-15 (251)

Average Cutting Data for HM390 TDCR 1505...FW-P Inserts

Workpiece material

ISO class Typical representative Cutting Max.

DIN/ Material Material Hardness, AISI/SAE/ Carbide speed D.O.C. Feed

ISO 513 No. Material Designation Condition HB ASTM DIN W.-Nr. grade vc [SFM] ap [inch] fz [IPT] Coolant

21 Aluminum-wrought alloy Not cureable 60 HB 1000 3.0255 1575-2100

22 Aluminum-wrought alloy Cured 100 HB 7050 3.4345 1310-1840

Aluminum-cast,

23 Not cureable 75 HB A360.2 3.2383 1575-2100

alloyed <12% Si

24 Aluminum-cast, alloyed Cured 90 HB 4218B 3.2371 1310-1840

N Aluminum-cast, High EN IC28 .512 .0031-.0087 Wet

25 130 HB A390.0 785-1050

alloyed >12% Si temperature AB-48100**

26 Copper alloys >1% Pb Free cutting 110 HB C 93800 2.1182 785-1050

27 Copper alloys Brass 90 HB C 86500 2.0592 785-1050

Electrolytic

28 Copper alloys 100 HB C 63000 2.0966 525-785

copper

* ISCAR material group in accordance with VDI 3323 standard

** Euronorm

For machining under unstable conditions, the recommended cutting data should be reduced by 20-30%

HM390 TDKT 1907 IC

Triangular Inserts with 3 INSL Rd°

Helical Cutting Edges for APMX

90° Shoulder Accuracy

S BS RE

Recommended

Dimensions Tough 1 Hard

Machining Data

IC330 IC845 IC830 IC5400 IC808 IC810 ap fz

Designation INSL IC S APMX RE BS (inch) (inch/t)

HM390 TDKT 1907PDTR .827 .551 .276 .630 .0315 .098 • • • • • • .047-.630 .0039-.0079

• For cutting speed recommendations, see pages 586-591

For tools, see pages: HM390 FTD-19 (253)

489