Page 130 - MILLING_CATALOG_INCH_2022_P361-P592

P. 130

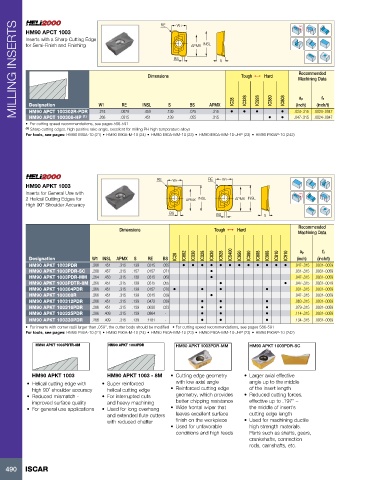

MILLING INSERTS HM90 APCT 1003 Dimensions BS W1 APMX INSL S Tough 1 Hard Recommended

RE

Rd°

Inserts with a Sharp Cutting Edge

for Semi-Finish and Finishing

Machining Data

fz

ap

Designation

RE

W1

BS

S

(inch)

(inch/t)

.0079

.315

.459

HM90 APCT 100302R-PDR

.274

•

(1)

.451

.268

.0315

.0024-.0047

HM90 APCT 100308-HP

.047-.315

.315

.055

.139

• For cutting speed recommendations, see pages 586-591 INSL .139 .075 APMX • IC28 • IC328 • IC928 • IC380 • IC808 .024-.315 .0024-.0047

(1) Sharp cutting edges, high positive rake angle, excellent for milling PH high temperature alloys

For tools, see pages: HM90 E90A-10 (21) • HM90 E90A-M-10 (24) • HM90 E90A-MM-10 (23) • HM90 E90A-MM-10-JHP (23) • HM90 F90AP-10 (242)

RE W1 RE W1

HM90 APKT 1003

Inserts for General Use with Rd°

2 Helical Cutting Edges for APMX INSL APMX INSL

High 90° Shoulder Accuracy

BS BS S

Recommended

Dimensions Tough 1 Hard

Machining Data

ap

fz

Designation W1 INSL APMX S RE BS IC28 IC882 IC330 IC328 IC830 IC928 IC5400 IC950 IC380 IC808 IC908 IC810 IC910 (inch) (inch/t)

HM90 APKT 1003PDR .266 .451 .315 .139 .0315 .055 • • • • • • • • • • • • .047-.315 .0031-.0059

HM90 APKT 1003PDR-SC .268 .457 .315 .157 .0157 .071 • .031-.315 .0031-.0059

HM90 APKT 1003PDR-MM .264 .453 .315 .138 .0315 .063 • .047-.315 .0031-.0059

HM90 APKT 1003PDTR-8M .266 .451 .315 .139 .0315 .055 • • .047-.315 .0031-.0079

HM90 APKT 100304PDR .266 .451 .315 .139 .0157 .070 • • • • .031-.315 .0031-.0059

HM90 APKT 100308R .266 .451 .315 .139 .0315 .039 • .047-.315 .0031-.0059

HM90 APKT 100312PDR .266 .451 .315 .139 .0472 .039 • • • .063-.315 .0031-.0059

HM90 APKT 100316PDR .266 .451 .315 .139 .0630 .023 • • • .079-.315 .0031-.0059

HM90 APKT 100325PDR .266 .409 .315 .139 .0984 - • • • .114-.315 .0031-.0059

HM90 APKT 100330PDR .266 .409 .315 .139 .1181 - • • • .134-.315 .0031-.0059

• For inserts with corner radii larger than .059", the cutter body should be modified • For cutting speed recommendations, see pages 586-591

For tools, see pages: HM90 E90A-10 (21) • HM90 E90A-M-10 (24) • HM90 E90A-MM-10 (23) • HM90 E90A-MM-10-JHP (23) • HM90 F90AP-10 (242)

HM90 APKT 1003PDTR-8M HM90 APKT 1003PDR HM90 APKT 1003PDR-MM HM90 APKT 1003PDR-SC

HM90 APKT 1003 HM90 APKT 1003 - 8M • Cutting edge geometry • Larger axial effective

• Helical cutting edge with • Super reinforced with low axial angle angle up to the middle

high 90˚ shoulder accuracy helical cutting edge • Reinforced cutting edge of the insert length

• Reduced mismatch - • For interrupted cuts geometry, which provides • Reduced cutting forces,

improved surface quality and heavy machining better chipping resistance effective up to .197” –

• For general use applications • Used for long overhang • Wide frontal wiper that the middle of insert’s

and extended flute cutters leaves excellent surface cutting edge length

with reduced chatter finish on the workpiece • Used for machining ductile

• Used for unfavorable high strength materials.

conditions and high feeds Parts such as shafts, gears,

crankshafts, connection

rods, camshafts, etc.

490 ISCAR