Page 131 - MILLING_CATALOG_INCH_2022_P361-P592

P. 131

W1

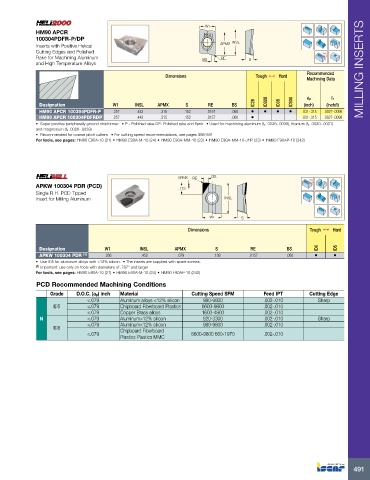

HM90 APCR

100304PDFR-P/DP

Inserts with Positive Helical APMX lNSL

Cutting Edges and Polished Rd°

Rake for Machining Aluminum BS RE S

and High Temperature Alloys MILLING INSERTS

Dimensions Tough 1 Hard Recommended

Machining Data

fz

ap

Designation W1 INSL APMX S RE BS IC28 IC928 IC08 IC908 (inch) (inch/t)

HM90 APCR 100304PDFR-P .257 .443 .315 .152 .0157 .060 • • • • .031-.315 .0027-.0098

HM90 APCR 100304PDFRDP .257 .443 .315 .152 .0157 .060 • .031-.315 .0027-.0098

• Super positive peripherally ground chipformer • P - Polished rake DP- Polished rake and flank • Used for machining aluminum (fz .0028-.0098), titanium (fz .0020-.0031)

and magnesium (fz .0020-.0039)

• Recommended for coarse pitch cutters • For cutting speed recommendations, see pages 586-591

For tools, see pages: HM90 E90A-10 (21) • HM90 E90A-M-10 (24) • HM90 E90A-MM-10 (23) • HM90 E90A-MM-10-JHP (23) • HM90 F90AP-10 (242)

APMX RE BS Rd°

APKW 100304 PDR (PCD) .173

Single R.H. PCD Tipped

Insert for Milling Aluminum INSL

W1 S

Dimensions Tough 1 Hard

Designation W1 INSL APMX S RE BS ID8 ID5

APKW 100304 PDR (1) .266 .452 .079 .138 .0157 .060 • •

• Use ID5 for aluminum alloys with <12% silicon. • The inserts are supplied with spare screws.

(1) Important: use only on tools with diameters of .787" and larger

For tools, see pages: HM90 E90A-10 (21) • HM90 E90A-M-10 (24) • HM90 F90AP-10 (242)

PCD Recommended Machining Conditions

Grade D.O.C. (ap) inch Material Cutting Speed SFM Feed IPT Cutting Edge

<.079 Aluminum alloys <12% silicon 980-9800 .002-.010 Sharp

ID5 <.079 Chipboard Fiberboard Plastics 6600-9800 .002-.010

<.079 Copper Brass alloys 1600-4900 .002-.010

N <.079 Aluminum>12% silicon 820-3300 .002-.010 Sharp

<.079 Aluminum<12% silicon 980-9800 .002-.010

ID8 Chipboard Fiberboard

<.079 6600-9800 660-1970 .002-.010

Plastics Plastics MMC

491