Page 48 - MILLING_CATALOG_INCH_2022_P361-P592

P. 48

SLOTTING & SLITTING CUTTERS

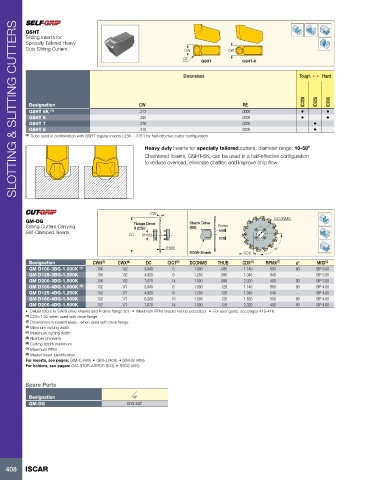

GSHT

Slitting Inserts for

Specially Tailored Heavy

Duty Slitting Cutters CW CW

RE GSHT GSHT-K

Dimensions Tough 1 Hard

Designation CW RE IC328 IC928 IC908

GSHT 6K (1) .213 .0000 • •

GSHT 6 .250 .0200 • •

GSHT 7 .276 .0200 •

GSHT 8 .315 .0200 •

(1) To be used in combination with GSHT regular inserts (.236 - .315") for half-effective cutter configuration

Heavy duty inserts for specially tailored cutters, diameter range: 10-58”.

Chamfered inserts, GSHT-6K, can be used in a half-effective configuration

to reduce overload, eliminate chatter, and improve chip flow.

CW

GM-DG Flange Drive Shank Drive DCONMS

Slitting Cutters Carrying R (CSI) (SS) Screw

Self-Clamped Inserts

DC DHUB

THUB a°

S/SW-Shank CDX

Designation CWN (3) CWX (4) DC CICT (5) DCONMS THUB CDX (6) RPMX (7) a° MIID (8)

GM D100-3DG-1.000K (1) .106 .132 3.940 6 1.000 .095 1.140 800 90 GIP 3.00

GM D125-3DG-1.250K .106 .132 4.920 8 1.250 .095 1.340 640 - GIP 3.00

GM D200-3DG-1.500K .106 .132 7.870 14 1.500 .095 2.320 400 90 GIP 3.00

GM D100-4DG-1.000K (2) .132 .171 3.940 6 1.000 .126 1.140 800 90 GIP 4.00

GM D125-4DG-1.250K .132 .171 4.920 8 1.250 .126 1.340 640 - GIP 4.00

GM D160-4DG-1.500K .132 .171 6.300 10 1.500 .126 1.530 500 90 GIP 4.00

GM D200-4DG-1.500K .132 .171 7.870 14 1.500 .126 2.320 400 90 GIP 4.00

• DHUB refers to SW/S drive shanks and R drive flange set • Maximum RPM should not be exceeded • For user guide, see pages 410-416

(1) CDX=1.02 when used with drive flange

(2) Dimensions in parentheses - when used with drive flange

(3) Minimum cutting width

(4) Maximum cutting width

(5) Number of inserts

(6) Cutting depth maximum

(7) Maximum RPM

(8) Master insert identification

For inserts, see pages: GIM-C (409) • GIM-J (409) • GIM-W (409)

For holders, see pages: CAT-STUB-ARBOR (623) • SW/S (405)

Spare Parts

Designation

GM-DG EDG 44A*

408 ISCAR