Page 53 - MILLING_CATALOG_INCH_2022_P361-P592

P. 53

USER GUIDE

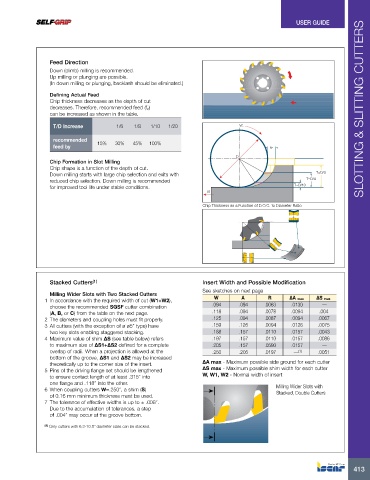

Feed Direction

Down (climb) milling is recommended.

Up milling or plunging are possible.

(In down milling or plunging, backlash should be eliminated.)

Defining Actual Feed

Chip thickness decreases as the depth of cut

decreases. Therefore, recommended feed (fz) SLOTTING & SLITTING CUTTERS

can be increased as shown in the table.

T/D Increase 1/6 1/8 1/10 1/20 Vc

recommended

feed by 15% 30% 45% 100% fz

D

Chip Formation in Slot Milling

Chip shape is a function of the depth of cut.

Down milling starts with large chip selection and exits with T=D/3

reduced chip selection. Down milling is recommended T=D/4

for improved tool life under stable conditions. T=D/10

Vf

Chip Thickness as a Function of D.O.C. to Diameter Ratio

Stacked Cutters (1) Insert Width and Possible Modification

See sketches on next page

Milling Wider Slots with Two Stacked Cutters

1 In accordance with the required width of cut (W1+W2), W A R ∆A max ∆S max

choose the recommended SGSF cutter combination .094 .094 .0063 .0130 —

(A, B, or C) from the table on the next page. .118 .094 .0078 .0094 .004

2 The diameters and coupling holes must fit properly. .125 .094 .0087 .0094 .0067

3 All cutters (with the exception of ø ø5” type) have .159 .126 .0094 .0126 .0075

two key slots enabling staggered stacking. .188 .157 .0110 .0157 .0043

4 Maximum value of shim ∆S (see table below) refers .197 .157 .0110 .0157 .0086

to maximum size of ∆S1+∆S2 defined for a complete .205 .157 .0590 .0157 —

overlap of radii. When a projection is allowed at the .250 .205 .0197 — (1) .0051

bottom of the groove, ∆S1 and ∆S2 may be increased

theoretically up to the corner size of the insert. ∆A max - Maximum possible side ground for each cutter

5 Pins of the driving flange set should be lengthened ∆S max - Maximum possible shim width for each cutter

to ensure contact length of at least .315” into W, W1, W2 - Normal width of insert

one flange and .118” into the other.

6 When coupling cutters W=.250”, a shim (S) Milling Wider Slots with

of 0.16 mm minimum thickness must be used. Stacked, Double Cutters

7 The tolerance of effective widths is up to ± .008”.

Due to the accumulation of tolerances, a step

of .004” may occur at the groove bottom.

(1) Only cutters with 6.3-10.0” diameter sizes can be stacked.

413