Page 112 - Aluminum_Machining_catalog_2023

P. 112

USER GUIDE

EXCHANGEABLE DRILLING HEADS

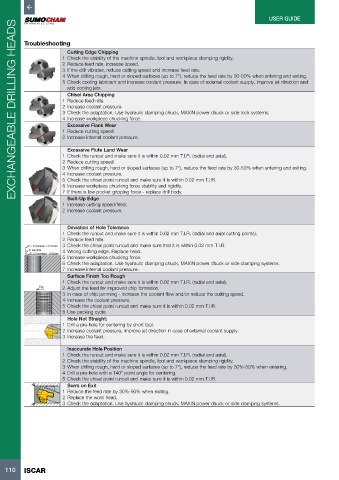

Troubleshooting

Cutting Edge Chipping

1 Check the stability of the machine spindle, tool and workpiece clamping rigidity.

2 Reduce feed rate, increase speed.

3 If the drill vibrates, reduce cutting speed and increase feed rate.

4 When drilling rough, hard or sloped surfaces (up to 7°), reduce the feed rate by 30-50% when entering and exiting.

5 Check cooling lubricant and increase coolant pressure. In case of external coolant supply, improve jet direction and

add cooling jets.

Chisel Area Chipping

1 Reduce feed rate.

2 Increase coolant pressure.

3 Check the adaptation. Use hydraulic clamping chuck, MAXIN power chuck or side lock systems.

4 Increase workpiece chucking force.

Excessive Flank Wear

1 Reduce cutting speed.

2 Increase internal coolant pressure.

Excessive Flute Land Wear

1 Check the runout and make sure it is within 0.02 mm T.I.R. (radial and axial).

2 Reduce cutting speed.

3 When drilling rough, hard or sloped surfaces (up to 7°), reduce the feed rate by 30-50% when entering and exiting.

4 Increase coolant pressure.

5 Check the chisel point runout and make sure it is within 0.02 mm T.I.R.

6 Increase workpiece chucking force stability and rigidity.

7 If there is low pocket gripping force - replace drill body.

Built-Up Edge

1 Increase cutting speed/feed.

2 Increase coolant pressure.

Deviation of Hole Tolerance

1 Check the runout and make sure it is within 0.02 mm T.I.R. (radial and axial cutting points).

2 Reduce feed rate.

Ø > D nominal + 0.15mm 3 Check the chisel point runout and make sure that it is within 0.02 mm T.I.R.

D nominal 4 Wrong cutting edge. Replace head.

Ø < D nominal - 0.03mm

5 Increase workpiece chucking force.

6 Check the adaptation. Use hydraulic clamping chuck, MAXIN power chuck or side clamping systems.

7 Increase internal coolant pressure.

Surface Finish Too Rough

1 Check the runout and make sure it is within 0.02 mm T.I.R. (radial and axial).

Ra 2 Adjust the feed for improved chip formation.

3 In case of chip jamming - increase the coolant flow and/or reduce the cutting speed.

4 Increase the coolant pressure.

5 Check the chisel point runout and make sure it is within 0.02 mm T.I.R.

6 Use pecking cycle.

Hole Not Straight:

1 Drill a pre-hole for centering by short tool.

2 Increase coolant pressure, improve jet direction in case of external coolant supply.

3 Increase the feed.

Inaccurate Hole Position

1 Check the runout and make sure it is within 0.02 mm T.I.R. (radial and axial).

2 Check the stability of the machine spindle, tool and workpiece clamping rigidity.

3 When drilling rough, hard or sloped surfaces (up to 7°), reduce the feed rate by 30%-50% when entering.

4 Drill a pre-hole with a 140° point angle for centering.

5 Check the chisel point runout and make sure it is within 0.02 mm T.I.R.

Burrs on Exit

1 Reduce the feed rate by 30%-50% when exiting.

2 Replace the worn head.

3 Check the adaptation. Use hydraulic clamping chuck, MAXIN power chuck or side clamping systems.

110 ISCAR