Page 27 - Aluminum_Machining_catalog_2023

P. 27

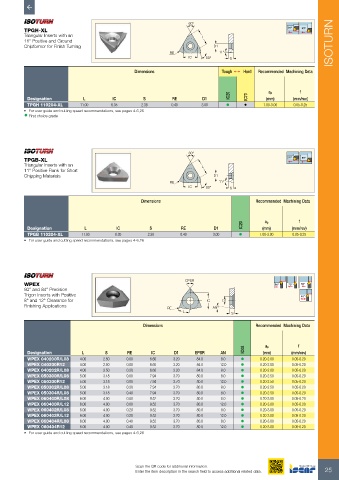

60°

TPGH-XL 91º 95º

Triangular Inserts with an L

11° Positive and Ground

Chipformer for Finish Turning D1 ISOTURN

RE 11°

IC 80° S

Dimensions Tough 1 Hard Recommended Machining Data

IC20 ap f

Designation L IC S RE D1 IC70 (mm) (mm/rev)

TPGH 110204-XL 11.00 6.35 2.38 0.40 3.00 • • 1.00-3.00 0.05-0.25

• For user guide and cutting speed recommendations, see pages 4-6,26

• First choice grade

60°

TPGB-XL 91º 95º

Triangular Inserts with an L

11° Positive Flank for Short

Chipping Materials D1

RE 11°

IC 80° S

Dimensions Recommended Machining Data

f

ap

Designation L IC S RE D1 IC20 (mm) (mm/rev)

TPGB 110204-XL 11.00 6.35 2.38 0.40 3.00 • 1.00-3.00 0.05-0.25

• For user guide and cutting speed recommendations, see pages 4-6,26

WPEX EPSR 90° 75° 60°

80° and 84° Precision

Trigon Inserts with Positive 45°

8° and 12° Clearance for IC D1

Finishing Applications RE AN°

L S

Dimensions Recommended Machining Data

IC08 ap f

Designation L S RE IC D1 EPSR AN (mm) (mm/rev)

WPEX 040200R/L08 4.00 2.50 0.00 6.60 3.20 84.0 8.0 • 0.20-2.00 0.05-0.20

WPEX 040200R12 4.00 2.50 0.00 6.60 3.20 84.0 12.0 • 0.20-2.00 0.05-0.20

WPEX 040202R/L08 4.00 2.50 0.20 6.60 3.20 84.0 8.0 • 0.20-2.00 0.05-0.20

WPEX 050300R/L08 5.00 3.18 0.00 7.94 3.70 80.0 8.0 • 0.20-2.50 0.05-0.20

WPEX 050300R12 5.00 3.18 0.00 7.94 3.70 80.0 12.0 • 0.20-2.50 0.05-0.20

WPEX 050302R/L08 5.00 3.18 0.20 7.94 3.70 80.0 8.0 • 0.20-2.50 0.05-0.20

WPEX 050304R/L08 5.00 3.18 0.40 7.94 3.70 80.0 8.0 • 0.20-2.50 0.05-0.20

WPEX 060400R/L08 6.00 4.00 0.00 9.52 3.70 80.0 8.0 • 0.20-3.00 0.05-0.20

WPEX 060400R/L12 6.00 4.00 0.00 9.52 3.70 80.0 12.0 • 0.20-3.00 0.05-0.20

WPEX 060402R/L08 6.00 4.00 0.20 9.52 3.70 80.0 8.0 • 0.20-3.00 0.05-0.20

WPEX 060402R/L12 6.00 4.00 0.20 9.52 3.70 80.0 12.0 • 0.20-3.00 0.05-0.20

WPEX 060404R/L08 6.00 4.00 0.40 9.52 3.70 80.0 8.0 • 0.20-3.00 0.05-0.20

WPEX 060404R12 6.00 4.00 0.40 9.52 3.70 80.0 12.0 • 0.20-3.00 0.05-0.20

• For user guide and cutting speed recommendations, see pages 4-6,26

Scan the QR code for additional information.

Enter the item description in the search field to access additional related data. 25