Page 30 - Aluminum_Machining_catalog_2023

P. 30

USER GUIDE

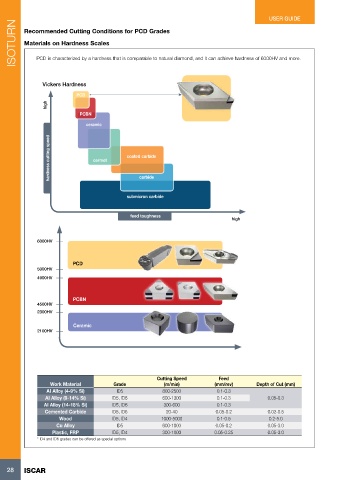

ISOTURN Materials on Hardness Scales

Recommended Cutting Conditions for PCD Grades

PCD is characterized by a hardness that is comparable to natural diamond, and it can achieve hardness of 6000HV and more.

Vickers Hardness

PCD

high

PCBN

ceramic

hardness cutting speed cermet coated carbide

carbide

submicron carbide

feed toughness

high

6000HV

PCD

5000HV

4900HV

PCBN

4500HV

2300HV

Ceramic

2100HV

Cutting Speed Feed

Work Material Grade (m/min) (mm/rev) Depth of Cut (mm)

AI Alloy (4-9% Si) ID5 800-2500 0.1-0.3

AI Alloy (9-14% Si) ID5, ID6 600-1300 0.1-0.3 0.05-0.3

AI Alloy (14-18% Si) ID5, ID6 300-600 0.1-0.3

Cemented Carbide ID5, ID6 20-40 0.05-0.2 0.02-0.5

Wood ID5, ID4 1000-5000 0.1-0.5 0.2-5.0

Cu Alloy ID5 600-1000 0.05-0.2 0.05-3.0

Plastic, FRP ID5, ID4 300-1000 0.05-0.25 0.05-3.0

* ID4 and ID6 grades can be offered as special options

28 ISCAR