Page 173 - MILLING CATALOG p319-550

P. 173

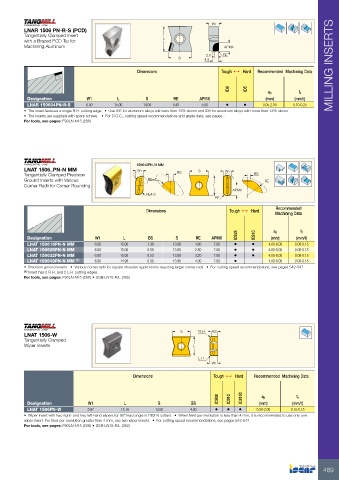

LNAR 1506 PN-R-S (PCD) L W1 ID8

Tangentially Clamped Insert ID5

with a Brazed PCD Tip for APMX

Machining Aluminum 2.0 RE MILLING INSERTS

4.5

S

Tough 1 Hard Recommended Machining Data

Dimensions

ap fz

(mm/t)

Designation W1 L S RE APMX •• (mm) 0.10-0.25

LNAR 150604PN-R-S 6.00 15.06 14.00 0.40 5.00 0.05-2.00

• The insert features a single R.H. cutting edge • Use ID5 for aluminum alloys with less than 12% silicon and ID8 for aluminum alloys with more than 12% silicon

• The inserts are supplied with spare screws • For D.O.C., cutting speed recommendations and grade data, see pages ..

For tools, see pages: F90LN-N15 (208)

LNAT 1506..PN-N MM 150640PN-N MM BS S W1 BS

Tangentially Clamped Precision W1

Ground Inserts with Various RE

Corner Radii for Corner Rounding RE=4

L

RE4.0 APMX

RE

Dimensions Tough 1 Hard Recommended

Machining Data

IC928 ap fz

IC910

Designation W1 L BS S RE APMX (mm) (mm/t)

• •

LNAT 150616PN-N MM 6.00 15.00 1.39 13.88 1.60 7.00 • • 4.00-8.00 0.08-0.15

LNAT 150625PN-N MM 6.00 15.00 0.60 13.88 2.50 7.00 • • 4.00-8.00 0.08-0.15

LNAT 150632PN-N MM 6.00 15.00 0.53 13.88 3.20 7.00 4.00-8.00 0.08-0.15

13.96 4.00 7.00 •

LNAT 150640PN-N MM (1) 6.00 14.98 0.00 4.00-8.00 0.08-0.15

• Precision ground inserts • Various corner radii for square shoulder applications requiring larger corner radii • For cutting speed recommendations, see pages 542-547

(1) Insert has 2 R.H. and 2 L.H. cutting edges.

For tools, see pages: F90LN-N15 (208) • SSB-LN15-R/L (362)

LNAT 1506-W S R.H BS

Tangentially Clamped

Wiper Inserts L

Dimensions L.H Recommended Machining Data

W1

Tough 1 Hard

IC908 ap fz

IC910

Designation W1 L S BS IC4100 (mm) (mm/t)

LNAT 1506PN-W 5.97 15.18 13.85 4.80 ••• 0.50-2.00 0.10-0.15

• Wiper insert with two right- and two left-hand wipers for 90° lead angle in F90LN cutters • When feed per revolution is less than 4 mm, it is recommended to use only one

wiper insert. For feed per revolution greater than 4 mm, use two wiper inserts • For cutting speed recommendations, see pages 542-547

For tools, see pages: F90LN-N15 (208) • SSB-LN15-R/L (362)

489