Page 172 - MILLING CATALOG p319-550

P. 172

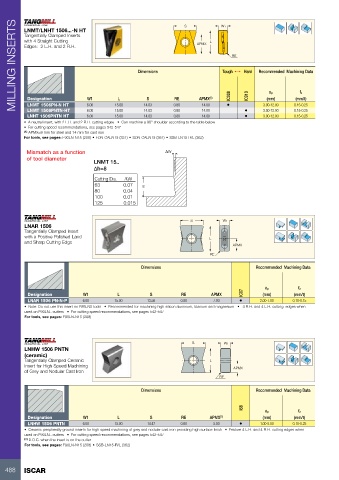

MILLING INSERTS LNMT/LNHT 1506...-N HT S W1

Tangentially Clamped Inserts

with 4 Straight Cutting APMX L

Edges: 2 L.H. and 2 R.H.

RE

Dimensions Tough 1 Hard Recommended Machining Data

IC928 ap fz

IC910

Designation W1 L S RE APMX(1) (mm) (mm/t)

14.00 •

LNMT 1506PN-N HT 6.00 15.00 14.03 0.80 3.00-12.00 0.15-0.25

• 3.00-12.00 0.15-0.25

LNMT 1506PNTN-HT 6.00 15.00 14.03 0.80 14.00 • 3.00-12.00 0.15-0.25

LNHT 1506PNTN HT 6.00 15.00 14.03 0.80 14.00

• A neutral insert, with 2 L.H. and 2 R.H. cutting edges • Can machine a 90° shoulder according to the table below

• For cutting speed recommendations, see pages 542-547

(1) APMX=9 mm for steel and 14 mm for cast iron

For tools, see pages: F90LN-N15 (208) • FDN-CALN15 (351) • SDN-CALN15 (361) • SSB-LN15-R/L (362)

Mismatch as a function ∆W

of tool diameter

LNMT 15..

Δh=8

Cutting Dia. ∆W 8

63 0.07

80 0.04

100 0.01

125 0.015

LNAR 1506 S W1

Tangentially Clamped Insert

with a Positive Polished Land L

and Sharp Cutting Edge APMX

Dimensions RE

Recommended Machining Data

IS8 IC07 ap fz

Designation W1 L S RE APMX (mm) (mm/t)

0.10-0.15

LNAR 1506 PN-N-P 6.00 15.00 13.56 0.80 7.00 • 2.00-7.00

• Note: Do not use this insert on F86LNX tools • Recommended for machining high silicon aluminum, titanium and magnesium • 4 R.H. and 4 L.H. cutting edges when

used on F90LN.. cutters • For cutting speed recommendations, see pages 542-547

For tools, see pages: F90LN-N15 (208)

S W1

LNHW 1506 PNTN L APMX

(ceramic) RE

Tangentially Clamped Ceramic

Insert for High Speed Machining

of Grey and Nodular Cast Iron

Dimensions Recommended Machining Data

ap fz

Designation W1 L S RE APMX(1) (mm) (mm/t)

• 1.00-5.00

LNHW 1506 PNTN 6.00 15.00 14.47 0.80 5.00 0.15-0.25

• Ceramic peripherally ground inserts for high speed machining of grey and nodular cast iron providing high surface finish • Feature 4 L.H. and 4 R.H. cutting edges when

used on F90LN.. cutters • For cutting speed recommendations, see pages 542-547

(1) D.O.C. when the insert is on the cutter

For tools, see pages: F90LN-N15 (208) • SSB-LN15-R/L (362)

488 ISCAR