Page 171 - MILLING CATALOG p319-550

P. 171

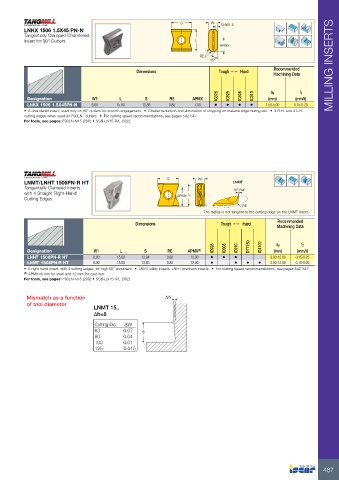

LNKX 1506 1.5X45 PN-N S W1 CHW1.5 IC328

Tangentially Clamped Chamfered IC928

Insert for 90° Cutters L IC908

APMX IC910

Dimensions Recommended

RE MILLING INSERTSMachining Data

45°

Tough 1 Hard

ap fz

Designation W1 L S RE APMX (mm) (mm/t)

LNKX 1506 1.5X45PN-N 6.00 15.00 13.88 7.00 • • • • 1.50-5.00

0.80 0.15-0.20

• A chamfered insert, used only on 90° cutters for smooth engagement • Chatter reduction and elimination of chipping on material edge during exit • 4 R.H. and 4 L.H.

cutting edges when used on F90LN.. cutters • For cutting speed recommendations, see pages 542-547

For tools, see pages: F90LN-N15 (208) • SSB-LN15-R/L (362)

LNMT/LNHT 1506PN-R HT S W1 LNMT

Tangentially Clamped Inserts APMX L 10° Ref.

with 4 Straight Right-Hand

Cutting Edges

RE

The radius is not tangent to the cutting edge on the LNMT insert.

Dimensions Tough 1 Hard Recommended

Machining Data

IC928 ap fz

IC908

Designation W1 L S RE APMX(1) IC910 (mm) (mm/t)

LNHT 1506PN-R HT DT7150

LNMT 1506PN-R HT IC4100

6.00 15.00 13.94 0.80 12.00 • • • 3.00-12.00 0.15-0.25

12.00 • • • • 3.00-12.00

6.00 15.00 13.93 0.80 0.15-0.20

• A right-hand insert, with 4 cutting edges, for high 90° shoulders • LNMT-utility inserts, LNHT-precision inserts • For cutting speed recommendations, see pages 542-547

(1) APMX=9 mm for steel and 12 mm for cast iron

For tools, see pages: F90LN-N15 (208) • SSB-LN15-R/L (362)

Mismatch as a function ∆W

of tool diameter

LNMT 15..

Δh=8

Cutting Dia. ∆W 8

63 0.07

80 0.04

100 0.01

125 0.015

487