Page 65 - MILLING_CATALOG_INCH_2022_P1-P92

P. 65

LF Rd°

KAPR THSZMS

MM EFF DC DCONMS

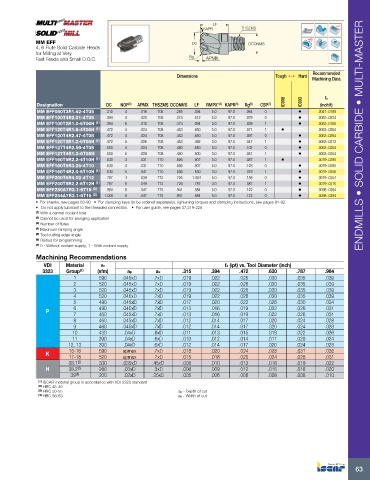

4, 6 Flute Solid Carbide Heads

for Milling at Very

Fast Feeds and Small D.O.C. Rg APMX

Dimensions Tough 1 Hard Recommended

Machining Data

IC908 IC903 fz

Designation DC NOF (3) APMX THSZMS DCONMS LF RMPX° (4) KAPR (5) Rg (6) CSP (7) (inch/t)

MM EFF080T3R1.62-4T05 .315 4 .016 T05 .295 .394 5.0 97.0 .064 0 • .0047-.0189

MM EFF100T4R2.01-4T06 .394 4 .020 T06 .374 .512 5.0 97.0 .079 0 • .0063-.0224

MM EFF100T2R1.0-6T06H (1) .394 6 .018 T06 .374 .394 3.0 97.0 .039 1 • .0063-.0185

MM EFF120T4R1.8-4T08H (1) .472 4 .024 T08 .453 .650 5.0 97.0 .071 1 • .0063-.0264

MM EFF120T4R2.47-4T08 .472 4 .024 T08 .453 .650 5.0 97.0 .097 0 • .0063-.0264 ENDMILLS • SOLID CARBIDE • MULTI-MASTER

MM EFF120T2R1.2-6T08H (1) .472 6 .026 T08 .453 .492 3.0 97.0 .047 1 • .0063-.0213

MM EFF127T4R2.59-4T08 .500 4 .024 T08 .480 .650 5.0 97.0 .102 0 • .0063-.0264

MM EFF127T4R1.3-6T08H .500 6 .028 T08 .480 .500 3.0 97.0 .051 1 • .0063-.0264

MM EFF160T5R2.2-4T10H (1) .630 4 .031 T10 .606 .807 5.0 97.0 .087 1 • .0079-.0295

MM EFF160T5R3.25-4T10 .630 4 .031 T10 .606 .807 5.0 97.0 .128 0 • .0079-.0295

MM EFF160T4R2.0-6T10H (1) .630 6 .041 T10 .606 .630 3.0 97.0 .079 1 • .0079-.0256

MM EFF200T6R4.02-4T12 .787 4 .039 T12 .726 1.004 5.0 97.0 .158 0 • .0079-.0354

MM EFF200T5R2.2-6T12H (1) .787 6 .049 T12 .726 .787 3.0 97.0 .087 1 • .0079-.0315

MM EFF250A7R3.1-6T15 (2) .984 6 .047 T15 .941 .984 5.0 97.0 .122 0 • .0098-.0394

MM EFF254A7R3.1-6T15 (2) 1.000 6 .047 T15 .941 .984 5.0 97.0 .122 0 • .0098-.0394

• For shanks, see pages 83-90 • For clamping keys (to be ordered separately), tightening torques and clamping instructions, see pages 91-92

• Do not apply lubricant to the threaded connection. • For user guide, see pages 37,219-228

(1) With a central coolant hole

(2) Cannot be used for plunging application

(3) Number of flutes

(4) Maximum ramping angle

(5) Tool cutting edge angle

(6) Radius for programming

(7) 0 - Without coolant supply, 1 - With coolant supply

Machining Recommendations

VDI Material vc fz (ipt) vs. Tool Diameter (inch)

3323 Group (1) (sfm) ap ae .315 .394 .472 .630 .787 .984

1 590 .045xD .7xD .019 .022 .026 .030 .035 .039

2 520 .045xD .7xD .019 .022 .026 .030 .035 .039

3 520 .045xD .7xD .019 .022 .026 .030 .035 .039

4 520 .045xD .7xD .019 .022 .026 .030 .035 .039

5 490 .045xD .7xD .017 .020 .022 .026 .030 .034

6 490 .045xD .7xD .013 .016 .019 .022 .026 .031

P

7 460 .045xD .7xD .013 .016 .019 .022 .026 .031

8 460 .045xD .7xD .012 .014 .017 .020 .024 .028

9 460 .045xD .7xD .012 .014 .017 .020 .024 .028

10 430 .04xD .6xD .011 .013 .015 .019 .022 .026

11 390 .04xD .6xD .010 .012 .014 .017 .020 .024

12, 13 390 .04xD .6xD .012 .014 .017 .020 .024 .028

K 15-16 590 apmax .7xD .018 .020 .024 .028 .031 .035

17-18 520 apmax .7xD .015 .018 .020 .024 .028 .031

38.1 (2) 330 .035xD .45xD .008 .010 .013 .016 .019 .022

H 38.2 (3) 260 .03xD .3xD .006 .009 .012 .015 .018 .020

39 (4) 200 .02xD .25xD .005 .006 .006 .008 .008 .010

(1) ISCAR material group in accordance with VDI 3323 standard

(2) HRC 45-49

(3) HRC 50-55 ap - Depth of cut

(4) HRC 56-63 ae - Width of cut

63