Page 70 - MILLING_CATALOG_INCH_2022_P1-P92

P. 70

LF

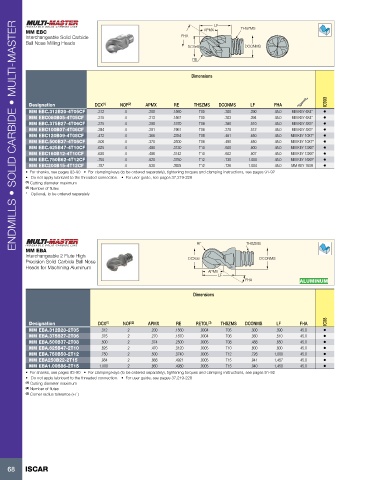

ENDMILLS • SOLID CARBIDE • MULTI-MASTER

MM EBC APMX THSZMS

Interchangeable Solid Carbide FHA

Ball Nose Milling Heads

DCXe8 DCONMS

RE

Dimensions

IC903

Designation DCX (1) NOF (2) APMX RE THSZMS DCONMS LF FHA

MM EBC.312B20-4T05CF .312 4 .200 .1560 T05 .300 .390 45.0 MM KEY 6X4* •

MM EBC080B05-4T05CF .315 4 .213 .1567 T05 .303 .394 45.0 MM KEY 6X4* •

MM EBC.375B27-4T06CF .375 4 .290 .1870 T06 .360 .510 45.0 MM KEY 8X5* •

MM EBC100B07-4T06CF .394 4 .291 .1961 T06 .378 .512 45.0 MM KEY 8X5* •

MM EBC120B09-4T08CF .472 4 .366 .2354 T08 .461 .650 45.0 MM KEY 10X7* •

MM EBC.500B37-4T08CF .500 4 .370 .2500 T08 .490 .650 45.0 MM KEY 10X7* •

MM EBC.625B47-4T10CF .625 4 .480 .3130 T10 .600 .800 45.0 MM KEY 13X8* •

MM EBC160B12-4T10CF .630 4 .488 .3142 T10 .602 .807 45.0 MM KEY 13X8* •

MM EBC.750B62-4T12CF .750 4 .620 .3750 T12 .730 1.000 45.0 MM KEY 16X9* •

MM EBC200B15-4T12CF .787 4 .630 .3925 T12 .726 1.004 45.0 MM KEY 16X9 •

• For shanks, see pages 83-90 • For clamping keys (to be ordered separately), tightening torques and clamping instructions, see pages 91-92

• Do not apply lubricant to the threaded connection. • For user guide, see pages 37,219-228

(1) Cutting diameter maximum

(2) Number of flutes

* Optional, to be ordered separately

RE THSZMS

MM EBA

Interchangeable 2 Flute High DCXe8 DCONMS

Precision Solid Carbide Ball Nose

Heads for Machining Aluminum

APMX

LF

FHA ALUMINUM

Dimensions

Designation DCX (1) NOF (2) APMX RE RETOL (3) THSZMS DCONMS LF FHA IC08

MM EBA.312B20-2T05 .312 2 .200 .1560 .0004 T05 .300 .390 45.0 •

MM EBA.375B27-2T06 .375 2 .270 .1870 .0004 T06 .360 .510 45.0 •

MM EBA.500B37-2T08 .500 2 .374 .2500 .0005 T08 .488 .650 45.0 •

MM EBA.625B47-2T10 .625 2 .470 .3120 .0005 T10 .600 .800 45.0 •

MM EBA.750B50-2T12 .750 2 .500 .3740 .0005 T12 .726 1.000 45.0 •

MM EBA250B22-2T15 .984 2 .866 .4921 .0005 T15 .941 1.457 45.0 •

MM EBA1.00B86-2T15 1.000 2 .860 .4980 .0005 T15 .940 1.450 45.0 •

• For shanks, see pages 83-90 • For clamping keys (to be ordered separately), tightening torques and clamping instructions, see pages 91-92

• Do not apply lubricant to the threaded connection. • For user guide, see pages 37,219-228

(1) Cutting diameter maximum

(2) Number of flutes

(3) Corner radius tolerance (+/-)

68 ISCAR