Page 17 - Turning_catalog_INCH_2022_45_P261-508

P. 17

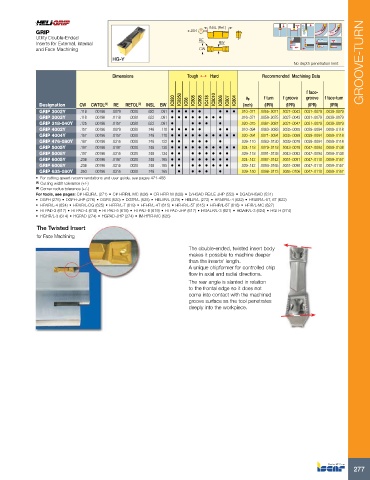

GRIP ±.004 INSL (Ref.)

Utility Double-Ended RE

Inserts for External, Internal BW

and Face Machining CW

No depth penetration limit GROOVE-TURN

Dimensions Tough 1 Hard Recommended Machining Data

f face-

IC830 IC8250 IC08 IC808 IC908 IC418 IC5010 IC806 IC807 IC804 ap f turn f groove groove f face-turn

Designation CW CWTOL (1) RE RETOL (2) INSL BW (inch) (IPR) (IPR) (IPR) (IPR)

GRIP 3002Y .118 .00196 .0079 .0020 .622 .091 • • • • • • • • .010-.071 .0055-.0071 .0027-.0043 .0031-.0079 .0039-.0079

GRIP 3003Y .118 .00196 .0118 .0020 .622 .091 • • • • • • • • .016-.071 .0059-.0075 .0027-.0043 .0031-.0079 .0039-.0079

GRIP 318-040Y .125 .00196 .0157 .0020 .622 .091 • • • • • .020-.075 .0067-.0087 .0027-.0047 .0031-.0079 .0039-.0079

GRIP 4002Y .157 .00196 .0079 .0020 .748 .110 • • • • • • • .010-.094 .0063-.0083 .0035-.0055 .0039-.0094 .0059-.0118

GRIP 4004Y .157 .00196 .0157 .0020 .748 .110 • • • • • • • • • • .020-.094 .0071-.0094 .0035-.0059 .0039-.0094 .0059-.0118

GRIP 476-080Y .187 .00196 .0315 .0020 .748 .122 • • • • • • .039-.110 .0083-.0130 .0039-.0079 .0039-.0094 .0059-.0118

GRIP 5005Y .197 .00196 .0197 .0020 .748 .130 • • • • • • • • • • .024-.118 .0079-.0118 .0043-.0079 .0047-.0094 .0059-.0138

GRIP 5008Y .197 .00196 .0315 .0020 .748 .134 • • • • • • • • .039-.118 .0091-.0138 .0043-.0083 .0047-.0094 .0059-.0138

GRIP 6005Y .236 .00196 .0197 .0020 .748 .165 • • • • • • • • .024-.142 .0087-.0142 .0051-.0091 .0047-.0110 .0059-.0157

GRIP 6008Y .236 .00196 .0315 .0020 .748 .165 • • • • • • • • .039-.142 .0094-.0165 .0051-.0098 .0047-.0110 .0059-.0157

GRIP 635-080Y .250 .00196 .0315 .0020 .748 .165 • • • • • .039-.150 .0098-.0173 .0055-.0106 .0047-.0110 .0059-.0157

• For cutting speed recommendations and user guide, see pages 471-488

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

For tools, see pages: C#-HELIR/L (271) • C#-HFIR/L-MC (626) • CR HFIR-M (628) • D/HGAD RE/LE-JHP (553) • DGAD/HGAD (531)

• DGFH (275) • DGFH-JHP (276) • DGFS (520) • DGTR/L (525) • HELIIR/L (379) • HELIR/L (272) • HFAER/L-4 (622) • HFAER/L-5T, 6T (622)

• HFAIR/L-4 (624) • HFAIR/L-DG (625) • HFFR/L-T (619) • HFHR/L-4T (615) • HFHR/L-5T (615) • HFHR/L-6T (616) • HFIR/L-MC (627)

• HFPAD-3 (617) • HFPAD-4 (618) • HFPAD-5 (618) • HFPAD-6 (619) • HFPAD-JHP (617) • HGAER/L-3 (621) • HGAIR/L-3 (624) • HGFH (274)

• HGHR/L-3 (614) • HGPAD (274) • HGPAD-JHP (274) • IM-HFIR-MC (626)

The Twisted Insert

for Face Machining

The double-ended, twisted insert body

makes it possible to machine deeper

than the inserts’ length.

A unique chipformer for controlled chip

flow in axial and radial directions.

The rear angle is slanted in relation

to the frontal edge so it does not

come into contact with the machined

groove surface as the tool penetrates

deeply into the workpiece.

277